What is the difference between corrugated plastic sheet and polypropylene honeycomb panel?

What is the difference between corrugated plastic sheet and polypropylene honeycomb panel?

Both corrugated plastic sheet and polypropylene honeycomb panel are a high technology hollow structure with features such as lightweight,non-toxic,waterproof,anti-termite,vibration damping,anti-aging and corrosion resistant.

Through adjusting formula or the chemical treatment of the surface, these polypropylene sheets have excellent performance on properties such as easy printing, UV resistance, flame retardant,electrical conduction and anti-static.

ESD Anti-static polypropylene sheets can be tailored to offer electrical properties spanning the surface resistivity spectrum from 106 to 1010 ohm/sq.

Conductive polypropylene sheets can be tailored to offer electrical properties spanning the surface resistivity spectrum from 103 to 105 ohm/sq.

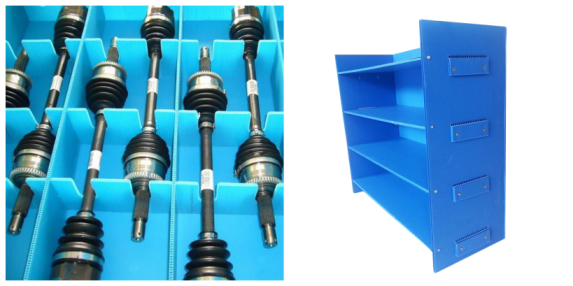

Conductive Turnover Boxes

Workpiece Container

But what is the difference between corrugated plastic sheet and polypropylene honeycomb panel?

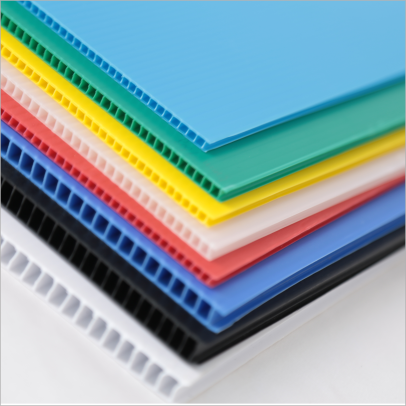

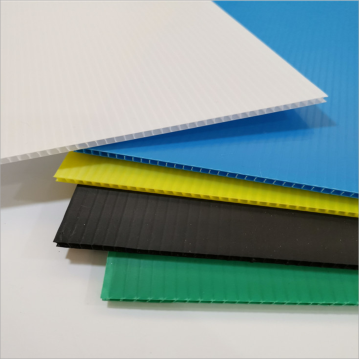

1. Color

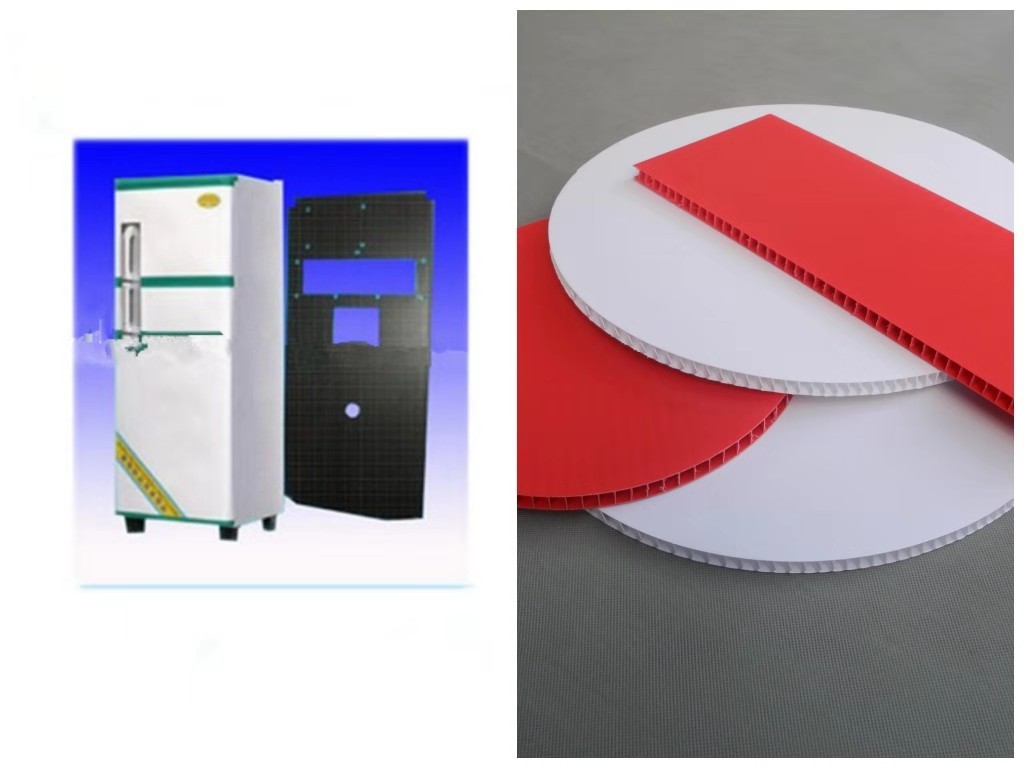

Corrugated plastic sheet is very rich in color. The commonly used colors are: white, yellow, green, blue, red, black, gray etc.Color can also be customized, reaching 90% close to the original.

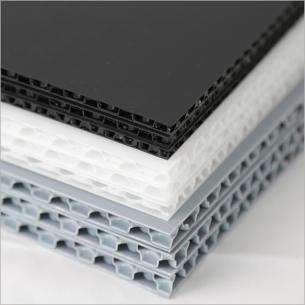

The color of polypropylene honeycomb panel is mainly gray, followed by black and white. The color can also be customized.But due to high processing cost, the customized color is higher than that of corrugated plastic sheet.

Corrugated plastic sheet has twin wall profile extrusion, joined by series of vertical ribs.

Line pattern surface

Wave Pattern Surface

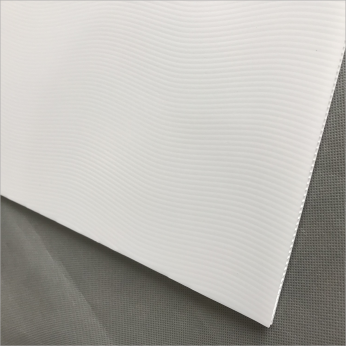

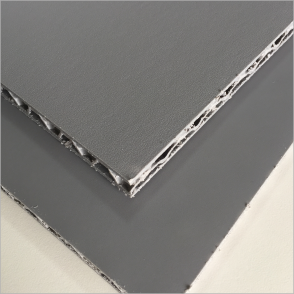

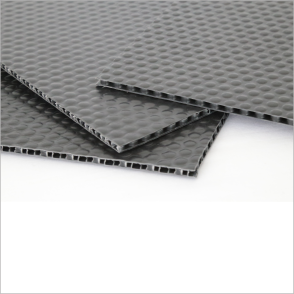

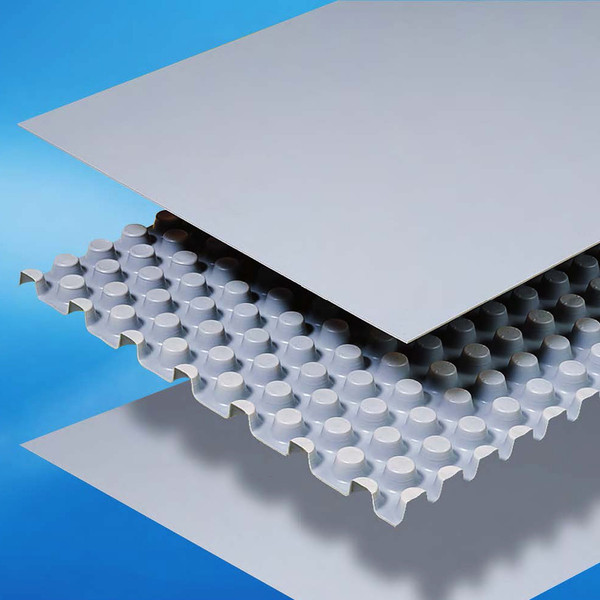

Polypropylene honeycomb panel is a sandwich structure with a honeycomb structure inside and two flat surfaces with either a bubble format or matte finish.

Matte Finish Surface

Bubble Format Surface

Honeycomb Structure

When compared with corrugated plastic sheet,honeycomb panel has a better performance on resistance to high strength,impact and bendingstresses, and on sound absorption and vibration damping as well due to its different structure.

4. Application

The main application of corrugated plastic sheet:

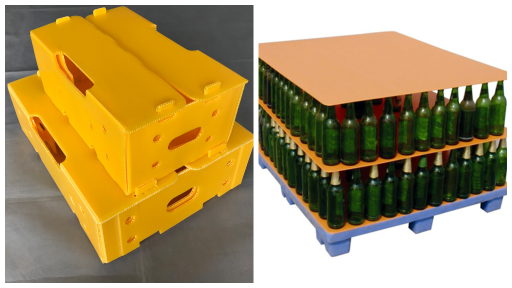

l Turnover boxesof holding fruit or orchids

l Turnover boxes of electrical & electronic appliance

l Turnover boxes of carry-home packs of beverages

l Unit/bulk packs of pharmaceuticals

Industrial usage board such as

wire/cable wrapping,

glass/steel board wrapping,

cushion,rack,

clapboard,

padding board,

luggage carrier,

separating board,

baseboard,

cross board,

etc.

Electronic industry packaging

Electrical and electronic components can be destroyed by electrostatic discharge. Conductive PP corrugated box / sheet prevents the generation of electrostatic charges and conducts previously existing charges away in a controlled manner.

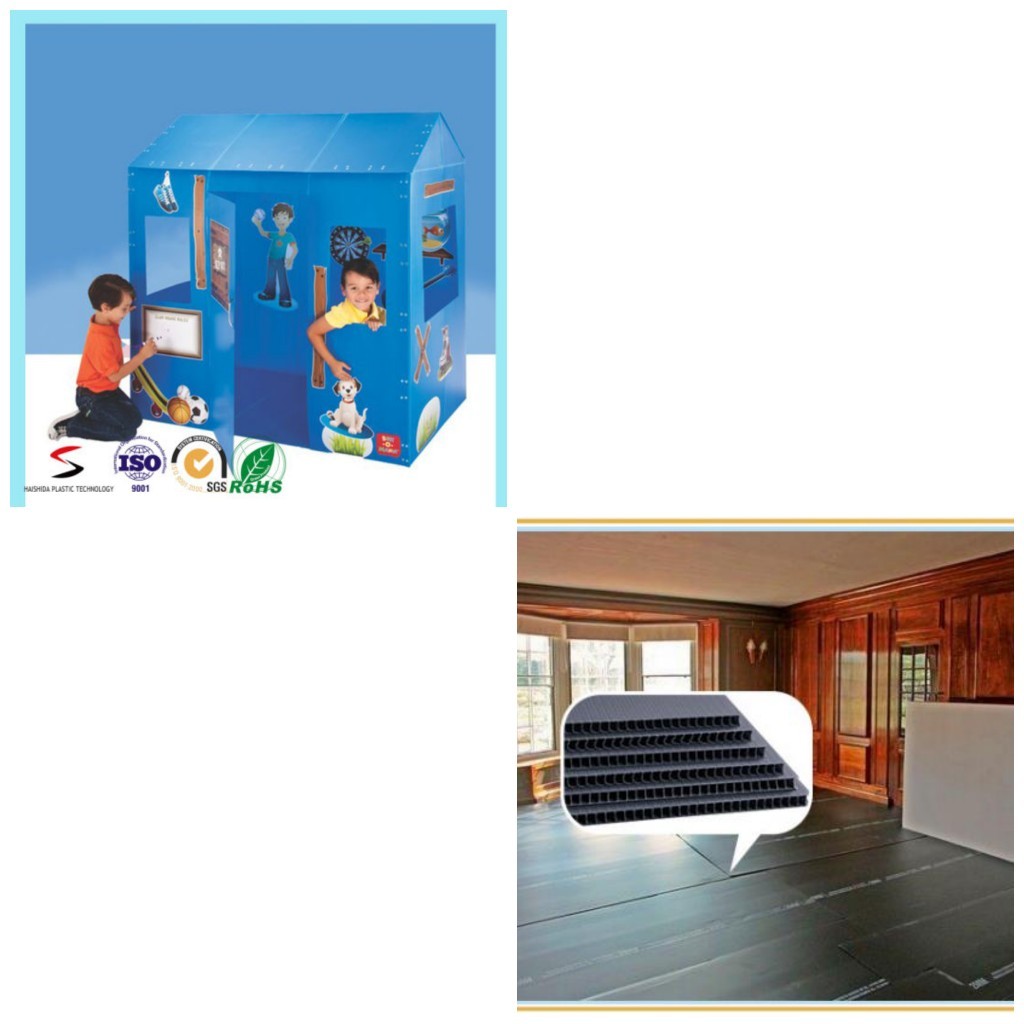

Advertising

Through corona treatment,

PP hollow sheet can be used as

advertising board,

show board, brand mark,

light box board,etc.

Household use

temporary plastic partition wall,

wall covering protection,

roofing sheets,

container covers etc.

Others application

water heaters,

baby carriages

cars, etc.

Main applications of PP honeycomb panel:

l heavier duty containers / Sleeve-pack/ Foldable containers

l smaller (foldable) packaging boxes

l pastic pallet

honeycomb flat panel for curtain wall

billboard with high stiffness

boats, yachts and ships

interior aircraft structural panels

plastic partition wall and merchandise display stand

caravan,motorhome,commercial transport vehicle and container truck body

automotive and transportation industries

non-woven fabric honeycomb board for trunk mat