The Difference of Production Technology and Performance between HDPE and UHMW-PE

The Difference of Production Technology and Performance between HDPE and UHMW-PE

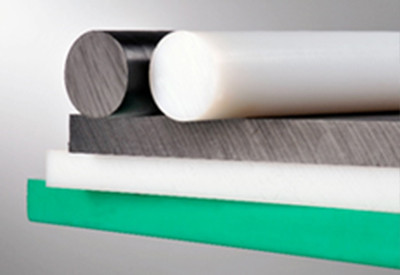

Generally HDPE’s production technology is extrusion, including three roll calender process and plate shaping process.

And the production technology of ultra-high molecular weight PE (UHMW-PE) is compression molding pressing.

In terms of thickness, the two types of products can be divided as:

1. Less than 25mm, the PE sheets are usually produced by extrusion calender process.

2. More than 25mm, the PE sheets can be produced either by extrusion plate shaping or by compression molding pressing.

The sheets produced by calender process, with very smooth surface, shinning like a mirror.

The sheets produced by compression molding pressing process, with not smooth and shinning surface.

HDPE usually refers to the PE sheet with molecular weight less than 1.5 million;

High molecular weight PE refers to PE sheet with molecular weight more than 3 million; There are 3 million, 5 million, 7.5 million, 10 million etc. molecular weight PE. The higher the molecular weight, the better the wear resistance.

Ultra-high molecular weight PE has excellent properties of wear resistance, impact resistance, low temperature resistance, corrosion resistance, sanitation and non-toxicity.

Wear-resistance testing method:

1. Make the workpiece for wear-resistant testing first;

2. Place the workpiece in the wear-resisting testing instrument, continuously wear the workpiece at the set speed and time;

3. The whole testing takes at least 3 hours.

Performance differences between HDPE and UHMW PE:

Chemical resistance: both materials have excellent chemical resistance and can be used in 95% chemical environments.

HDPE can't resist the corrosion of concentrated hydrochloric acid, sulfuric acid and nitric acid in high temperature, and UHMW-PE can be used to store 80 ° C hot concentrated hydrochloric acid, sulfuric acid and nitric acid, and have stable performance.

Impact resistance: HDPE and UHMW-PE have much better impact resistance than other plastics, such as PP, PVC. To Compare HDPE and UHMW-PE, the impact resistance of UHMW-PE is obviously better than that of HDPE, and its impact resistance absorption value is the highest among all plastics. Therefore, it is widely used in the mechanical workpieces of ships, aircraft and machine tools.

Low temperature resistance: HDPE can maintain good mechanical properties at low temperature - 30 ° C. UHMW-PE can still maintain excellent impact strength at -196 ° C in the liquid nitrogen, not brittle. Among all plastics, UHMW-PE has the best low temperature resistance.