Tips on How to Distinguish Good and Bad PVC Foam Board

sourcewww.boardwaybuilding.com

publisherBoardway

time2022/06/30

- It's critical to quickly identify good PVC foam board from those poor quality boards on the market. In this blog, we'll share some tips for judging PVC foam board from the buyer's point of view.

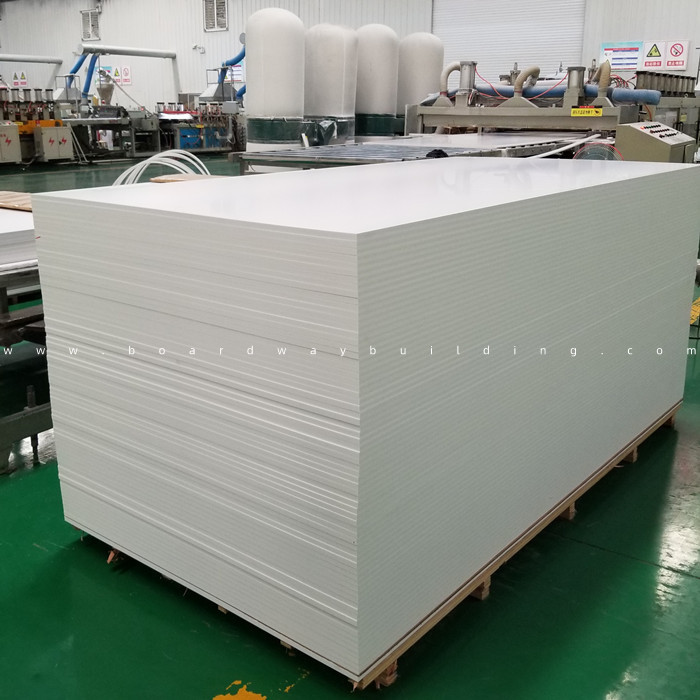

With the advantages of light weight, environment-friendly, recyclable, waterproof and fireproof, PVC foam board is widely used in advertising, interior decoration, furniture industry, vehicle liner, construction and even agriculture industry. It is the ideal material for printing signs, billboards, bathroom and kitchen cabinets, building materials in the humid environment, etc.

There are many PVC foam board suppliers in China. You can easily find them on Google and get samples from them. But how to compare these samples? Or compare the quality from trial order?

Knowing how to distinguish PVC foam boards can help you quickly find the better one among the many suppliers. To distinguish whether the quality of PVC foam board is good or bad, we can check it by smelling, touching and looking.

Smell the PVC foam board

The PVC raw material itself is odorless. However, in order to produce various PVC products, different additives have to be added to the raw materials. Some auxiliaries are odorous, so the PVC foam board after adding odorous auxiliaries also becomes odorous. Therefore, we say that the odor of PVC foam board is actually determined by additives.

The raw materials and equipment for the production of PVC foam board are matched with each other. Generally speaking, each factory has its own set of PVC foam board production formula. The PVC foam board produced by some formulas is odorless, while some PVC foam boards are odorous. Even if it smells, don't worry, it's still non-toxic and can be used normally.

However, if you happen to get a sample with a distinctly pungent odor, unfortunately it's a PVC foam board made from low-quality recycled plastic. You can just cross him off in your supplier list.

Touch the surface and sides of the PVC foam board

A good quality PVC foam board should be smooth to the touch without any bumps and pits. Especially PVC celuka foam board and PVC Co-extrusion foam board, their surface is smooth and hard.

When we touch the sides of the PVC foam board, there should be almost no powder falling off (a small amount of powder falling off is normal).

If there is a lot of powder on your hands, there are two possible reasons. One is that the factory has not cleaned the board thoroughly. The second is that the filler in the PVC foam board is too much added. Filler is the necessary raw material for the production of PVC foam board. However, if more fillers are added, the toughness and anti-aging ability of the PVC foam board will be reduced. Adding fillers is the most direct way to reduce the cost of boards, which is why some factories sell PVC foam boards at very low prices.

Pit on the board surface

Such a small amount of powder falling off is normal

Visually inspect the surface and sides of the PVC foam board

SURFACE

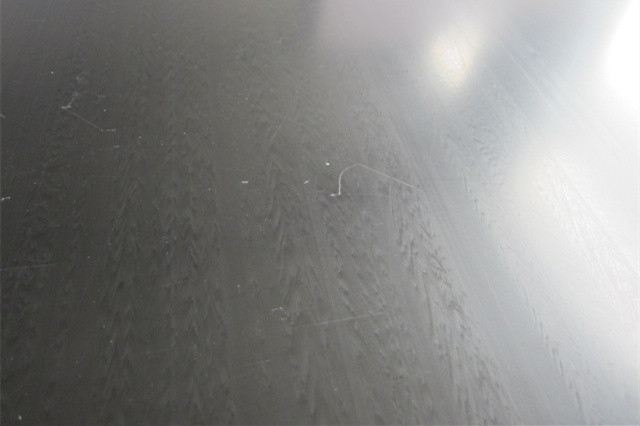

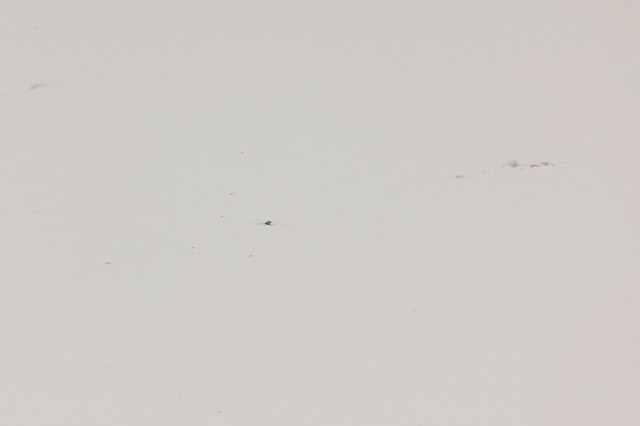

When inspecting the surface of the PVC foam board, what we need to pay attention to is whether there are mechanical lines, scratches, stains or impurities on the surface. The mechanical line generally comes from the equipment itself, reminding the factory that the equipment needs maintenance. The reason for the appearance of stains and impurities may be due to the poor hygiene of the production workshop. So that the impurities in the air and the stains on the equipment that have not been cleaned up in time are attached to the surface of the board. Scratches are mainly due to the fact that workers are not careful when lifting the sheets, causing them to scratch each other.

In one case, these defects may not affect the visual effect of the product, that is, the use of PVC foam board requires filming or printing and painting on its surface, and they are sufficient to cover the surface defects.

If it is a colored PVC foam board, we also need to pay attention to whether the color of the same board is uniform, and whether the color of different boards in the same batch is consistent. If the white PVC foam boards are black or gray when they are first received, then it may also be produced from poor quality raw materials and recycled plastics.

Mechanical lines on the board surface

Scratch on the board surface

Impurity on the board surface

Stains on the board surface

Observing the side of the board is actually to check the problem of the PVC foam board core. The most common defects on the side of the sheet are obvious large bubbles or visible continuous cells. This kind of problem is also the most troublesome, because it is usually hidden and difficult to detect. As long as the sheet is not cut apart, these problems may not be exposed. But if the PVC foam board needs to be cut to size or engraved, or made into an openwork panel, they will definitely be exposed.

Friends who know our company know that in addition to manufacturing PVC sheets, we also provide customized processing services. We have a processing factory in Dongguan City, Guangdong Province, providing customers with CNC cutting, printing, edge banding, assembly and other services.

A customer once shipped his PVC foam board to our processing plant for cutting. The full form PVC foam board looks normal. But what surprised us was the continuous cells exposed after the sheet was cut small. The defects are so severe that this products has become the negative teaching material for the training our new employees. Please refer to the pictures below. (For those who want to know our final solution, please feel free to attach a screenshot of this blog and email to sale..........com)

Secondly, we also need to check the color of the side of the board, which can also help us judge the quality of the raw materials of the PVC foam board. The PVC foam board with black or grey core must be produced with poor quality raw materials. After all, such a sheet has poor physical properties and a shorter service life.

How do we reduce defective products?

Boardway manufactures and wholesales different types of PVC foam sheets, including PVC sign board, expanded PVC foam, Co-extruded PVC foam, PVC embossed board, and PVC foam board laminate.

We have strict standards for the selection and testing of raw materials, and will not buy and use inferior materials. During the production process, we strictly control the product quality, and QC monitors the product every 30 minutes. The higher the customer's requirements for PVC sheets, the more frequent QC inspections are. After the production is completed, we randomly inspect or fully inspect the batch of goods to reduce the probability of defective boards again.

In order to avoid PVC sheet defects caused by improper packaging, we provide a protective film to protect the surface of the sheet from scratches. For pallet-packed PVC foam board, we put MDF or cement board on the pallet and on top of the goods when packing. The top protective plate can prevent the goods from being damaged by the packing tape. The bottom protection board protects the board from burrs or raised nails on the wooden pallet. In addition, an additional layer or even three layers of cardboard corner guards will be added to provide multiple protections for the board.

Boardway has many years of experience in how to provide customers with good quality PVC sheets. Nevertheless, we are still learning to become better manufacturers, suppliers and partners.

Boardway is a Chinese manufacturer and supplier of PVC foam board. We have more than 15 years of experience in the manufacture and application of PVC foam board and other plastic sheets. If you would like to know more about PVC foam board, or you have the needs of custom PVC foam board, please feel free to WhatsApp Helen at +86 13828266785 or email us at sale..........com.