How to Choose the Right PVC Foam Board for My Application?

sourcewww.boardwaybuilding.com

publisherBoardway

time2022/08/31

- Different types of PVC foam board, and different densities, properties, packaging, how do I choose the best material for my application? Learn how to buy PVC sheet and tell suppliers about your needs.

PVC foam board refers to closed-cell expanded PVC board with many benefits such as light weight, waterproof, flame retardant, and easy processing. It is widely used in printing and display, furniture, interior and exterior decoration and building construction industry, and it is a highly practical multifunctional board.

The types of PVC foam board are PVC free foam board, PVC celuka board, PVC co-extrusion board and laminated PVC foam board. PVC foam board can even be customized according to performance needs. The combination of types and properties adds more options to PVC foam board, so how do I choose the best PVC foam board for my application?

As a PVC foam board supplier in China, our mission is to provide customers with the most ideal material for their requirements and applications. Therefore, when we receive inquiries about PVC foam boards from customers, we will always ask customers about their needs before quoting. For example, we will ask customers whether they have used PVC foam board before, what is the purpose of PVC foam board, what environment will it be used in, and what performance is the most concerned about. After a full understanding, we will recommend materials and provide prices for customers.

In this blog, we will share with you how to choose the right PVC foam board for your needs, and how to tell your suppliers about your requirements based on our more than 15 years of research and manufacturing experience of PVC foam board.

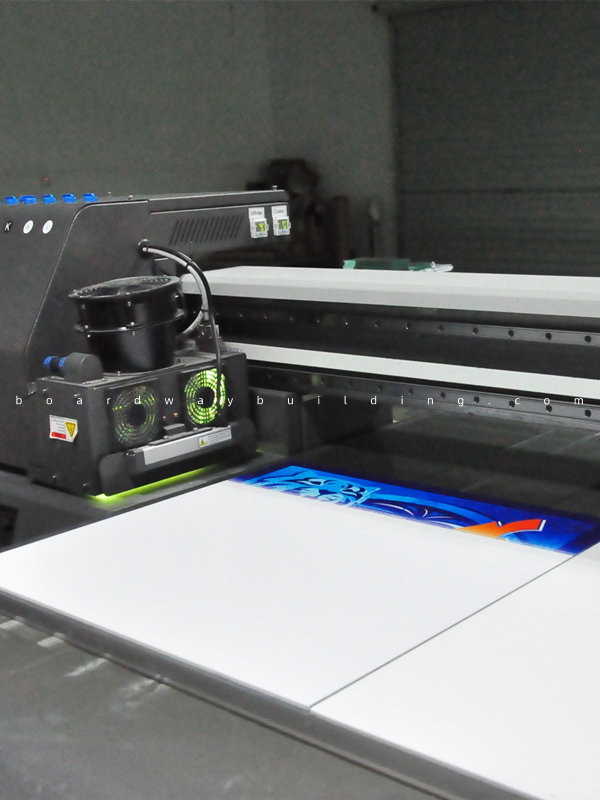

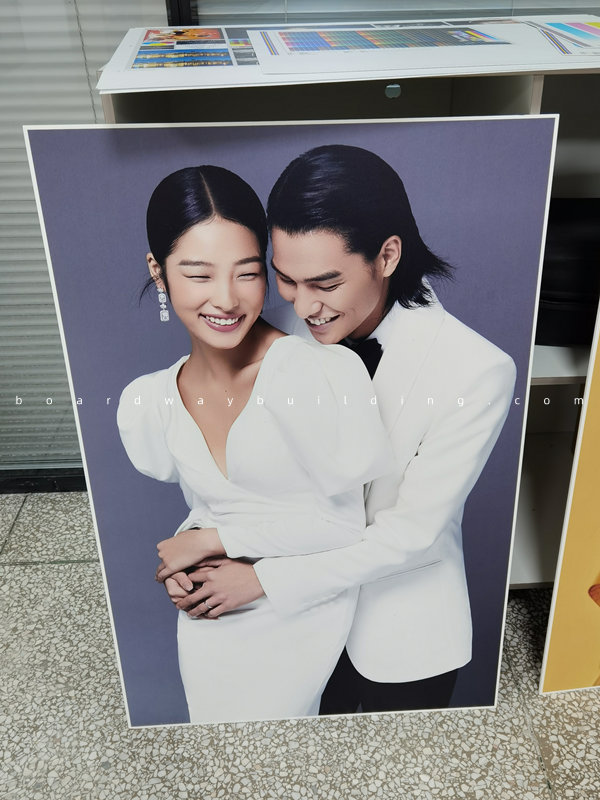

For the PVC foam board to be used for printing, we should pay attention to the printing quality, flatness and diagonal deviation of the PVC foam board.

1. Since it is used for printing, our first priority is to ensure its printability, that is, the printing ink is firm on its surface and not easy to fade. We strongly recommend that customers take samples from suppliers to test the printability of their materials before purchasing in bulk.

2. The PVC foam board should be flat enough with small diagonal deviation to ensure that it can be printed properly on the flatbed printer. Warped, or PVC foam sheets with large diagonal deviations may cause printing interruptions or even damage the printer. Therefore, when discussing the product with the supplier, we should also emphasize the flatness and diagonal deviation of the PVC foam sheet to the manufacturer. At the same time, ensure that the board is kept flat during transportation and storage.

3. If the printed display is large, our recommended material is PVC free foam board. It has bigger sizes like 1560x3050mm, 2050x3050mm.

4. Last but not least, buy PVC foam sheets with protective film. This ensures that the surface to be printed is not scratched or dusted. Single-sided or double-sided protective film is optional.

For the PVC foam board to be used as furniture, its hardness and impact resistance, screw holding power, thickness tolerance must be taken into consideration.

1. One of the most popular uses for PVC foam board is kitchen cabinets. Most cabinet manufacturers will use PVC foam board as cabinet body panels. The cabinet body panel plays an important role in the support of the entire cabinet, so the PVC foam board is required to have a good hardness and impact resistance.

2. To make cabinets, a large amount of hardware must be used, such as hinges, brackets, screws and so on. Whether these hardware parts can be stably assembled with the PVC foam board reflects the screw holding power of the PVC foam board. However, the screw-holding power of PVC foam board is closely related to its density. The higher the density of the PVC foam board, the better the screw holding power.

In order to make the PVC foam board have good hardness, impact resistance and screw holding power at the same time, we recommend increasing the proportion of PVC resin, reducing the filler, and the density of the board should be in the range of 0.55 to 0.65g/cm3. In addition, you can also ask the supplier to provide you with some test videos to prove the performance of their boards.

3. The last thing that is easily overlooked is the thickness tolerance of the PVC foam sheet. For example, the thickness tolerance of a PVC foam sheet with a thickness of 12mm is ±0.2mm, which means that the actual thickness of the sheet will be between 11.8mm and 12.2mm. If the PVC foam board needs to be inserted into the groove during installation, the thickness range of the groove must be informed to your PVC foam board supplier in advance. Only in this way can the thickness of the PVC foam board be less than the thickness of the groove so that it can be installed smoothly.

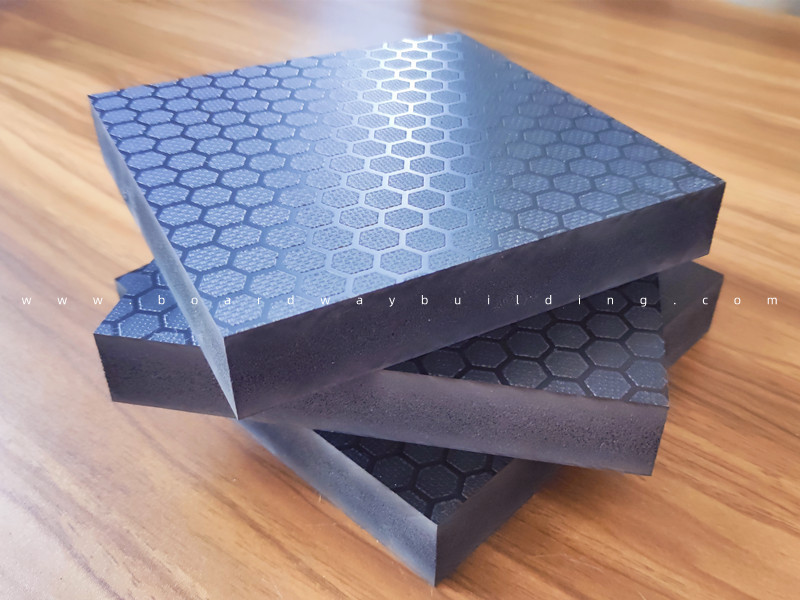

For the PVC foam board that will be CNC engraved into a hollow board, the quality of the core and the hardness are critical.

1. Engraving the PVC foam board into a hollow board is a big test of its quality. The hollowed-out design will expose the core of the PVC foam sheet, and directly see whether the internal foaming is uniform. The large cells exposed in the core will certainly greatly reduce the aesthetics and structural stability of the hollow board.

2. In addition, the more complex the hollow design, the higher the requirements for the hardness of the board. If the hardness of the PVC foam board is insufficient, and the hollow board does not have a good frame support, the hollow board may be bent and deformed.

3. For such applications, our recommended density for PVC foam board is between 0.5 and 0.65g/cm3.

If you are looking for a material for a new project or new design, then you can find the right PVC foam sheet from the performance requirements you need.

1. If PVC foam board with good scratch resistance is required, we recommend choosing PVC foam board with matt finish instead of smooth or glossy finish.

2. If you need a PVC foam board with better anti-skid properties for flooring, we strongly recommend our new product: PVC foam board with non-slip surface, which is specially designed for temporary platforms and mobile outdoor stages.

3. If the PVC foam board will be used outdoors, you may consider using the PVC foam board with enhanced UV resistance.

4. If you want a PVC foam sheet with a harder surface, PVC co-extruded sheet will be a good choice. Or if you want a variety of colors and designs to choose from, the laminated PVC foam board will definitely satisfy you.

We hope this blog can be helpful to customers who have PVC foam board needs. But if you still don't know how to choose the right PVC sheet for your application, please don't hesitate to contact us. We are more than happy to assist you.

Boardway is a Chinese manufacturer and supplier of PVC foam board. We have more than 15 years of experience in the manufacture and application of PVC foam board and other plastic sheets. If you would like to know more about PVC foam board, or you have the needs of custom PVC foam board, please feel free to WhatsApp Helen at +86 13828266785 or email us at sale..........com.

Boardway Processing Services

1. Cut to size and CNC engraving

2. Silk screen printing, digital printing, painting

3. Thermal processing, bending, embossing

4. Pre-drill, nail, screw and assemble

5. Sanding, PUR lamination, PVC edge banding

6. Corners and edges rounding, chamfering, grooved and tongued