What is Sanded PVC Foam Board? What's It For?

sourcewww.boardwaybuilding.com

publisherBoardway

time2022/10/13

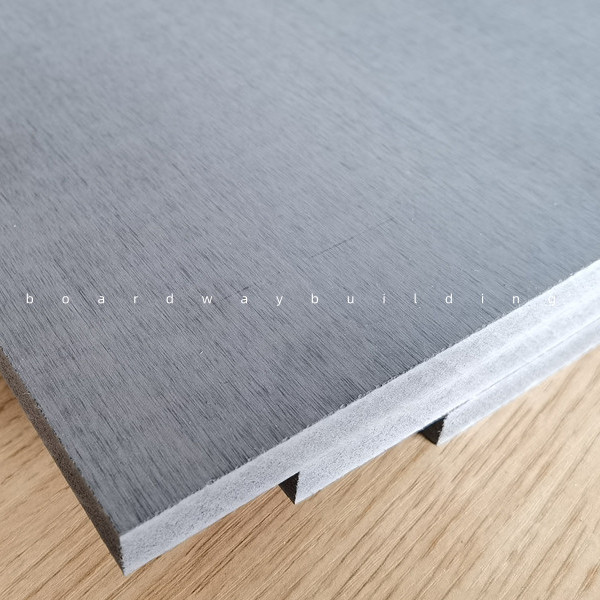

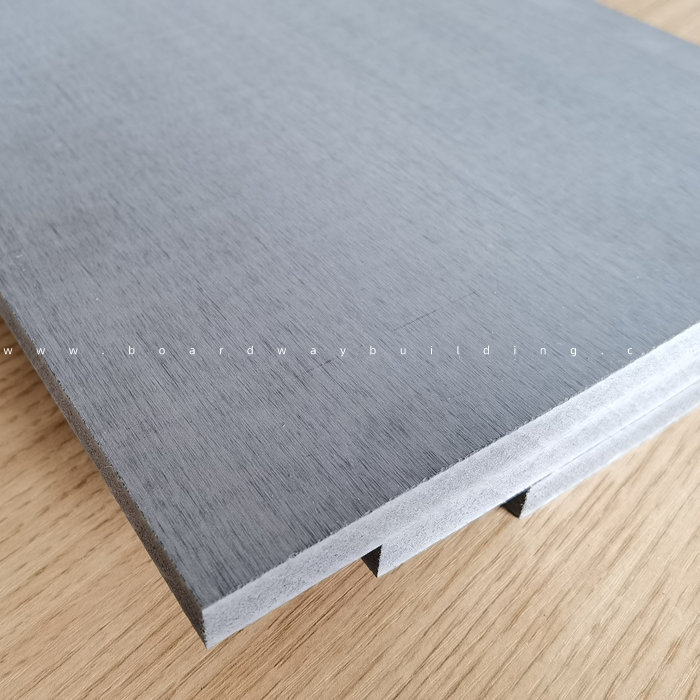

- Sanded PVC foam board is a PVC foam board whose surface has been sanded. Sanding treatment is helpful for the pasting or lamination of PVC foam boards.

As an ideal alternative for wood panels (MDF, particle board or plywood), PVC foam board works well in furniture boards, decoration panels and display boards. To be used for these purposes, we often need to do some processing such as painting, pasting, and lamination to the PVC foam board. Then we must first ensure that the PVC foam board has a good surface suitable for these processing.

The surface of the PVC foam board is hard and smooth. We can directly paint, paste, and laminate on it, and we can also sand the surface to get better processing results.

Sanding Treatment

The sanding process of PVC foam board involves using sandpaper or abrasive materials to abrade or smooth the surface of the board. It is a mechanical process that helps to remove imperfections, create a smoother texture, and prepare the surface for subsequent treatments or finishes.

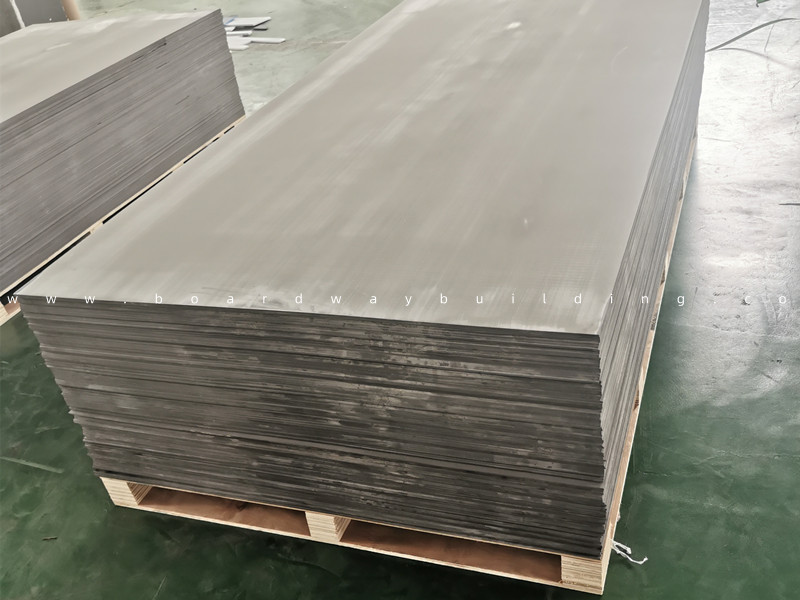

For small size and small number of PVC foam boards, you may use sandpaper to sand the PVC foam boards. For our factory, we have a sanding production line that can automatically sand the PVC foam board with full size, which is 1220x2440mm (4x8ft).

Why Sand the PVC Foam Board?

1. Smoothing the Surface

Sanding helps to smooth out any rough or uneven areas on the surface of the PVC foam board. It removes small imperfections, bumps, or texture irregularities, creating a more even and consistent surface.

2. Improving Adhesion

Sanding the surface of PVC foam board creates a slightly roughened texture, which improves the adhesion of adhesives, paints, or coatings that may be applied to the board. This enhanced adhesion ensures better bonding and durability of the applied materials.

3. Enhancing Paint Finish

Sanding the surface of PVC foam board provides better paint adhesion and promotes a smoother finish. It helps to create a surface that allows paint to adhere more effectively, reducing the risk of peeling, flaking, or uneven coverage.

4. Removing Gloss

PVC foam board often has a smooth, glossy surface, which may not be desirable for certain applications. Sanding helps to reduce the gloss and create a matte or semi-matte finish, providing a more aesthetic and suitable surface for specific uses.

But you may have such doubt:

Will the strength of the sanded PVC foam board be diminished?

In our practical application, we found that the performance of the sanded PVC foam board is the same as that of the non-sanded PVC foam board.

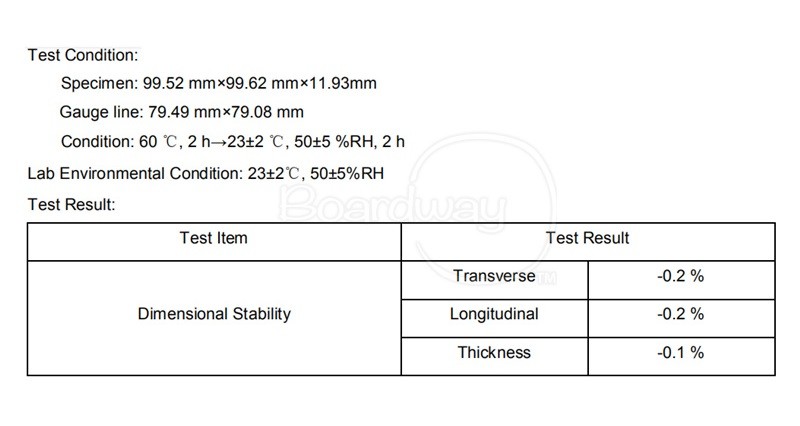

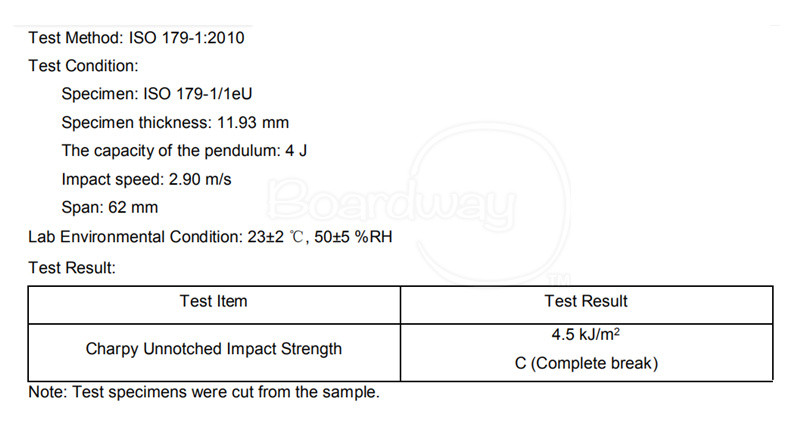

For more scientific proof, we sent the sanded PVC foam board to SGS laboratory for physical and mechanical tests. The results show that the data of the PVC foam board after sanding are all within the standard value.

It's important to note that not all PVC foam boards may require sanding, and the need for sanding depends on the specific application or desired outcome.

We provide paid sanding service for PVC foam board. If what you are looking for is better pasting or lamination processing quality and a longer service life for the finished product, we recommend that you choose a sanded PVC foam board. Your investment in it is definitely worth it.

Boardway is a Chinese manufacturer and supplier of PVC foam board. We have more than 15 years of experience in the manufacture and application of PVC foam board and other plastic sheets. If you would like to know more about PVC foam board, or you have the needs of custom PVC foam board, please feel free to WhatsApp Helen at +86 13828266785 or email us at sale..........com.

Boardway Processing Services

1. Cut to size and CNC engraving

2. Silk screen printing, digital printing, painting

3. Thermal processing, bending, embossing

4. Pre-drill, nail, screw and assemble

5. Sanding, PUR lamination, PVC edge banding

6. Corners and edges rounding, chamfering, grooved and tongued