How to Process PVC Foam Board Effectively?

sourcewww.boardwaybuilding.com

publisherBoardway

time2023/12/21

- Explore the art of effective PVC foam board processing! Discover expert techniques for crafting diverse DIY projects. From applications to custom designs, unleash your creativity with high-quality PVC foam board from a trusted manufacturer.

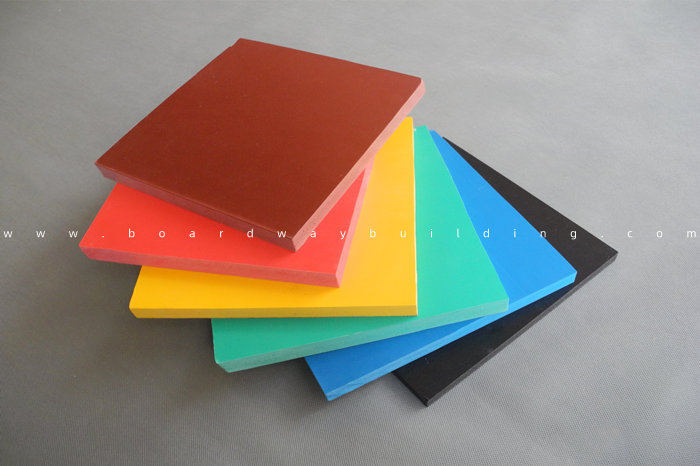

PVC foam board, a widely utilized material in various industries, boasts a unique set of properties that contribute to its popularity. Comprising a cellular structure, this board is not only lightweight but also exhibits remarkable durability and versatility. Its versatility makes it suitable for an array of applications, from signage to construction elements. However, to harness its full potential, proper processing is crucial. We share this article aims to guide you through the considerations and techniques necessary for optimizing your PVC foam board projects.

Section 1: Understanding PVC Foam Board Properties

Before we learn more about the intricacies of processing PVC foam board, it's imperative to grasp its fundamental properties. This material, often popular for its lightweight composition, is also distinguished by its durability and versatility. The lightweight nature ensures ease of handling and installation, while the durability makes it suitable for long-lasting applications. Its versatility is showcased in its adaptability to diverse projects, from intricate designs to robust construction elements. Un derstanding these properties is paramount, as it forms the foundation for making informed decisions during the processing stage. As we explore further, you'll discover how these characteristics influence the tools, techniques, and precautions necessary for successful PVC foam board processing.

Section 2: Tools, Equipment, and Cutting Techniques

Efficient processing of PVC foam board requires a careful selection of tools and mastery of appropriate techniques. Here's a comprehensive guide:

1. Utility Knife or PVC Cutter:

2. Jigsaw:

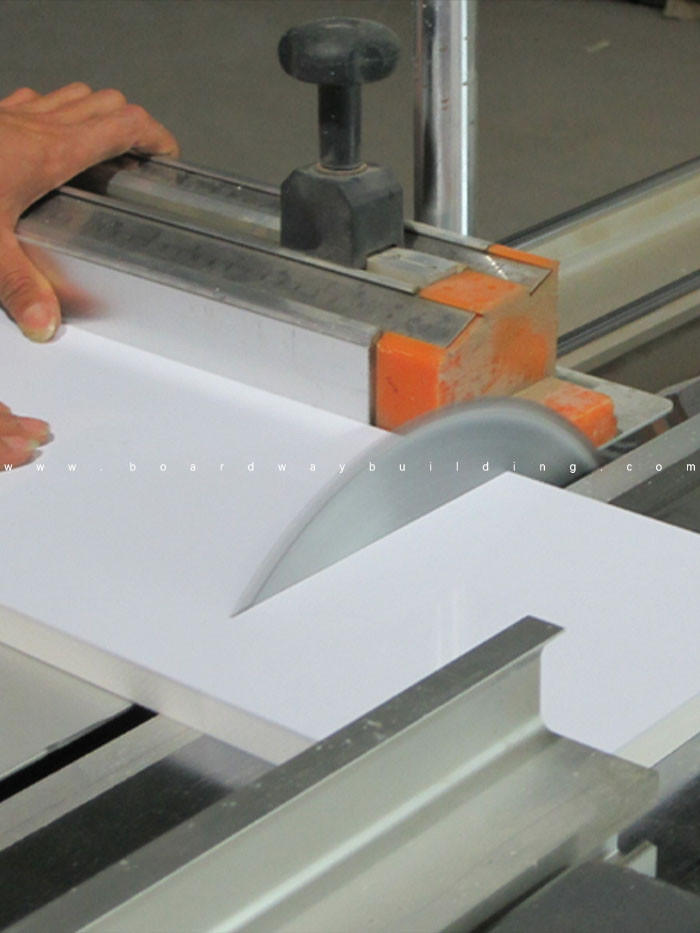

3. Circular Saw:Tool: For larger cutting tasks with straight lines. Technique: Adjust the blade depth for optimal results.

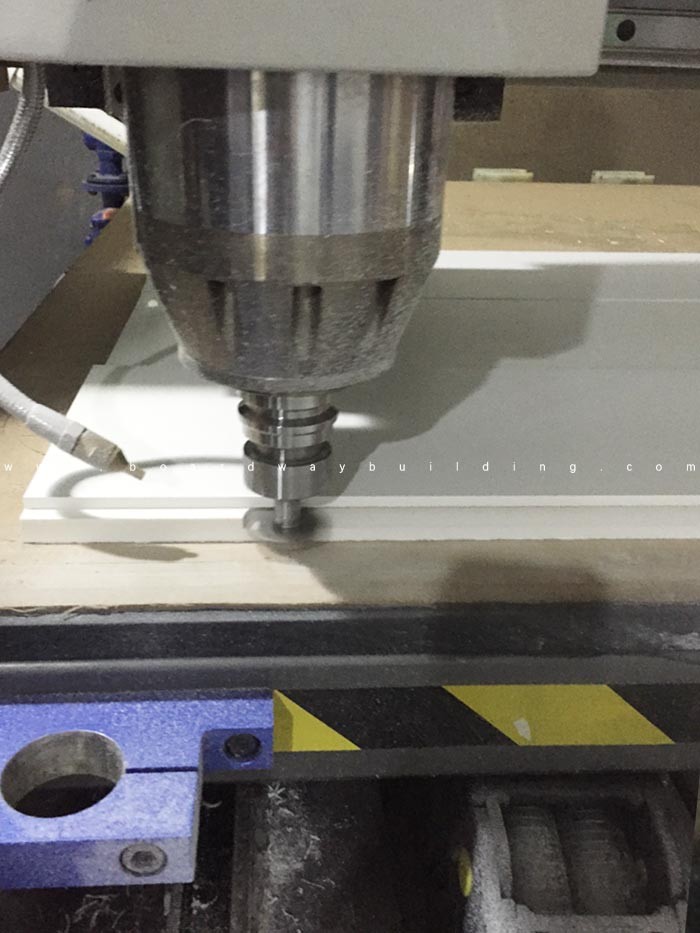

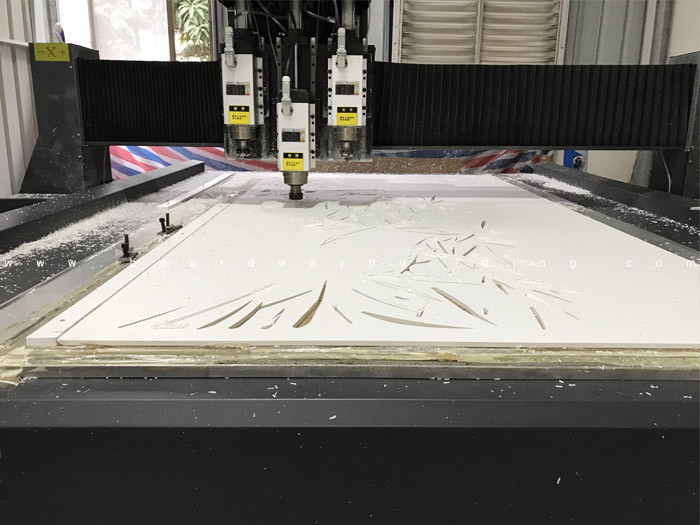

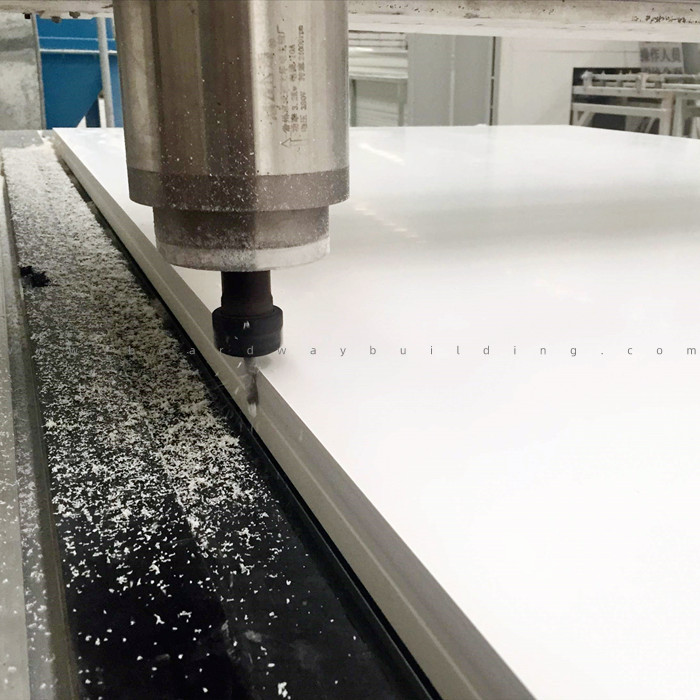

4. Router (CNC):Tool: Ideal for detailed edges, intricate designs, and decorative finishes. Technique: Utilize different router bits for varied effects.

5. Heat Gun:

6. Clamps:

7. Sanding Tools:Tool: Sandpaper or sanding block for a smooth finish. Technique: Achieve a polished and professional appearance.

8. Adhesive Application:Tool: Adhesive applicator. Technique: Apply adhesive evenly for a strong bond; follow recommended curing times.

The importance of using the appropriate tools cannot be overstated. Employing the wrong tools may not only compromise the quality of your project but can also lead to irreparable damage to the PVC foam board. It's crucial to avoid tools that generate excessive heat during the cutting process, such as laser cutters. PVC foam board is sensitive to high temperatures, and the use of heat-intensive tools can cause melting, deformation, and release of harmful fumes. Always prioritize the use of tools designed for plastic materials to ensure a smooth and damage-free processing experience. In the subsequent sections, we'll delve into the safety measures and techniques to maximize the efficacy of these tools in your PVC foam board projects.

Section 3: Safety Measures

While working with PVC foam board, prioritizing safety measures is paramount to ensure a secure and productive processing experience. Here are key precautions to consider:

1. Eye Protection:

Always wear safety goggles to shield your eyes from potential debris and particles generated during cutting and shaping.

2. Respiratory Protection:

Use a dust mask to prevent inhalation of PVC foam board particles. Adequate ventilation in the workspace is also essential.

3. Ear Protection:

When operating loud machinery like saws and routers, wearing ear protection is advised to prevent hearing damage.

4. Work Area Ventilation:

Ensure proper ventilation, especially when using adhesives or engaging in processes that release fumes. Work in a well-ventilated space or consider using an extraction system.

5. Tool-Specific Safety Gear:

Depending on the tool used, such as a router or jigsaw, employ specific safety gear. For instance, use appropriate heat-resistant gloves when handling a heat gun.

6. Secure Workpiece:

Use clamps or other securing methods to stabilize the PVC foam board during cutting and shaping, preventing unexpected movements.

7. Tool Maintenance:

Keep tools well-maintained and sharp to ensure clean cuts and efficient operation. Dull tools can lead to imprecise cuts and increased effort, posing safety risks.

8. Avoid Excessive Heat:

As PVC foam board is sensitive to high temperatures, refrain from using tools like laser cutters that generate excessive heat. Elevated temperatures can cause melting, deformation, and the release of harmful fumes.

9. Emergency Preparedness:

Know the location of emergency equipment, such as fire extinguishers, and have a clear understanding of emergency procedures.

By adhering to these safety measures, you not only protect yourself but also contribute to the overall success and quality of your PVC foam board projects. Safety should always be a priority in any workshop or processing environment.

Mastering the intricacies of PVC foam board processing is key to unlocking its full potential for your creative projects. From understanding its versatile properties to selecting the right tools and implementing safety measures, each step contributes to the success of your endeavors. Remember, safety is paramount, and using the appropriate tools is crucial for a smooth and damage-free processing experience.

Are you seeking not just effective processing but the mastery of every detail in your PVC foam board projects? Ready to elevate your craftsmanship to the next level? Dive into "How Can You Perfect Your PVC Foam Board Projects?" where we unravel the secrets of seamless connections, impeccable finishing touches, and the nuances of lamination for decoration. At Boardway, as China's premier manufacturer and supplier, we not only provide quality materials but also invite you to explore a world of creative possibilities through our customization services. Your journey to perfection starts here – click to unlock the full potential of PVC foam board in your hands.

At Boardway, we understand the importance of quality materials in your projects. As a leading manufacturer and supplier based in China, we take pride in providing high-quality PVC foam boards. Our commitment extends beyond delivering standard solutions – we offer customization services to meet your specific project requirements. Whether you're working on signage, furniture or construction elements, or intricate designs, Boardway is here to support your creative journey. Explore the possibilities, and let's craft excellence together.

- Experience the Best in PVC foam board with Boardway

- CONTACT NOW