The Applications of PVC Foam Board in Automotive Interior

sourcewww.boardwaybuilding.com

publisherBoardway

time2024/02/20

- Discover how PVC cabinets and various types of PVC foam board are utilized to customize vehicle interiors, offering versatility, durability, and aesthetic appeal. With customizable solutions and a range of design options, enhance the functionality and aesthetics of your vehicle interior with PVC foam board.

PVC foam board, a lightweight and versatile material, has increasingly become a preferred choice for enhancing automotive interiors. Renowned for its exceptional durability, ease of fabrication, and design versatility, PVC foam board offers a wide array of possibilities for interior customization in vehicles of various types.

RV PVC Cabinets

PVC Cabinets in Ambulances

Under Bench Storage

In recent years, there has been a notable surge in the utilization of PVC foam board across different segments of the automotive industry. From trailers and recreational vehicles (RVs) to ambulances and specialty vehicles, PVC foam board has found its way into a myriad of interior applications, revolutionizing the way vehicle interiors are designed and engineered.

This article aims to delve into the diverse applications of PVC foam board in automotive interior design, showcasing its adaptability and effectiveness in meeting the unique requirements of vehicle interiors. By exploring the growing trend of incorporating PVC foam board into interior modifications, we aim to provide valuable insights into its potential for enhancing both the functionality and aesthetics of automotive interiors. Join us as we embark on a journey to uncover the endless possibilities that PVC foam board offers in transforming the driving experience through innovative interior solutions.

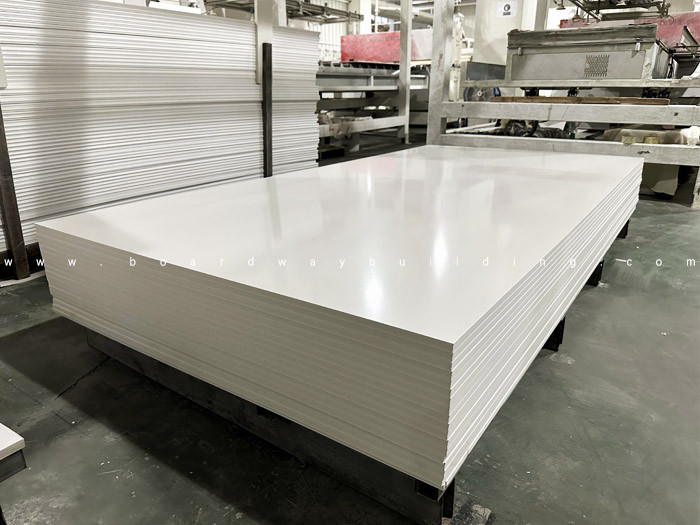

PVC Foam Board

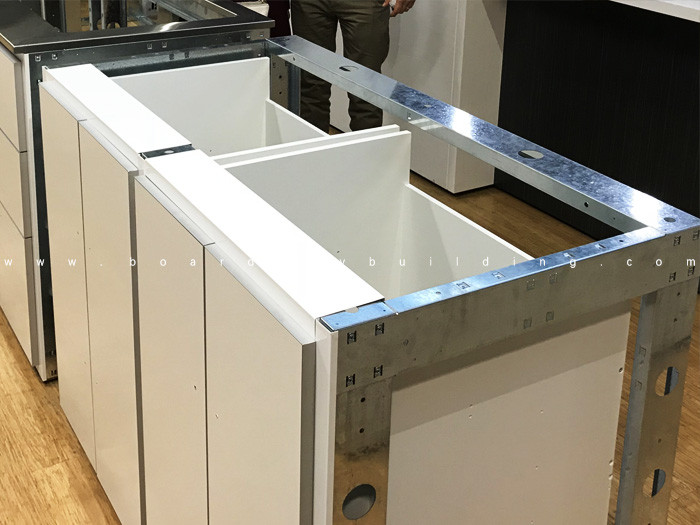

PVC Cabinets

Brief Description of PVC Foam Board

PVC foam board, also known as expanded PVC or foamex board, is a lightweight yet durable material widely used in various industries for its versatility and practicality. Composed of polyvinyl chloride (PVC) and foaming agents, PVC foam board exhibits exceptional durability, moisture resistance, and anti-corrosion properties, making it an ideal choice for applications where longevity and reliability are paramount.

One of the key advantages of PVC foam board is its resilience to environmental factors such as moisture, humidity, and corrosion. Unlike traditional materials like wood or metal, PVC foam board does not warp, rot, or corrode when exposed to moisture, making it suitable for use in kitchens, bathrooms or semi-outdoor areas where humidity levels can fluctuate.

PVC Foam Board Applications in Automotive Interior

a. Cabinetry and Storage Solutions

In the realm of automotive interior design, cabinetry and storage solutions play a vital role in optimizing space and organization. PVC foam board, with its versatility and structural integrity, offers a practical solution for fabricating storage units that are both functional and aesthetically pleasing.

Whether it's constructing overhead cabinets for storing essentials in an RV, designing built-in cabinets inside trailers that integrate cooking functionalities, such as stovetops, ovens, and food storage compartments, or configuring modular storage compartments in an ambulance, PVC foam board proves to be an excellent choice. Its ability to withstand varying environmental conditions, including temperature fluctuations and moisture exposure, ensures long-lasting performance in demanding automotive environments.

b. Decorative Trim and Accents

Decorative trim and accents play a crucial role in enhancing the visual appeal and ambiance of vehicle interiors. PVC foam board, with its ease of customization and compatibility with different finishing techniques, offers endless possibilities for achieving desired design aesthetics.

Whether it's adding crown molding to accentuate the elegance of an RV interior, installing chair rail molding to create a sophisticated look in a trailer, or incorporating decorative panels to infuse personality into an ambulance interior, PVC foam board provides designers and manufacturers with the flexibility to bring their creative visions to life.

c. Electrical Enclosures and Control Panels

Within the realm of automotive interior electronics, reliability and efficiency are paramount. PVC foam board offers the necessary qualities to meet these requirements, providing a stable and secure housing solution for sensitive electrical equipment.

Whether it's designing an enclosure for a fuse box in an RV, constructing a control panel for HVAC systems in a trailer, or fabricating a power distribution unit for medical equipment in an ambulance, PVC foam board delivers the durability and functionality needed to ensure the seamless operation of automotive interior electronics.

Benefits of Using PVC Foam Board in Automotive Interior

PVC foam board offers a multitude of advantages for interior modifications in vehicles, making it a preferred choice among designers, manufacturers, and vehicle owners alike. Below are the key benefits of utilizing PVC foam board in automotive interior applications:

1. Lightweight Construction

PVC foam board is renowned for its lightweight nature, making it an ideal material for interior modifications in vehicles. Its low density contributes to reduced vehicle weight, resulting in improved fuel efficiency and enhanced maneuverability.

2. Durability

Despite its lightweight composition, PVC foam board exhibits remarkable durability and resilience to mechanical stress and impact. It withstands everyday wear and tear, ensuring long-lasting performance in demanding automotive environments.

3. Anti-Rot Properties

PVC foam board is inherently resistant to rot, decay, and moisture absorption, making it suitable for use in automotive interiors where exposure to humidity and environmental elements is common. Its anti-rot properties contribute to the longevity and structural integrity of vehicle components.

4. Ease of Fabrication

One of the standout features of PVC foam board is its ease of fabrication and workability. It can be easily cut, shaped, routed, and bonded using standard woodworking tools and techniques, allowing for seamless customization and integration into various interior design schemes.

5. Cost-Effectiveness

PVC foam board offers a cost-effective solution for interior modifications in vehicles compared to traditional materials such as wood, metal, or fiberglass. Its affordability, coupled with its durability and ease of fabrication, results in overall cost savings without compromising quality or performance.

6. Design Versatility

PVC foam board lends itself to a wide range of design possibilities, thanks to its versatility and compatibility with various finishing techniques. Whether it's creating sleek and modern cabinetry, intricate decorative accents, or functional enclosures, PVC foam board allows for endless customization to suit different aesthetic preferences and functional requirements.

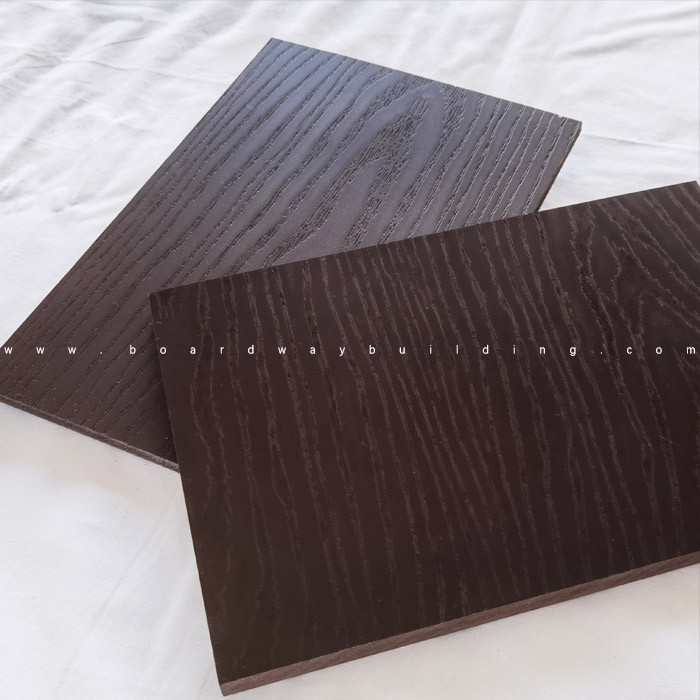

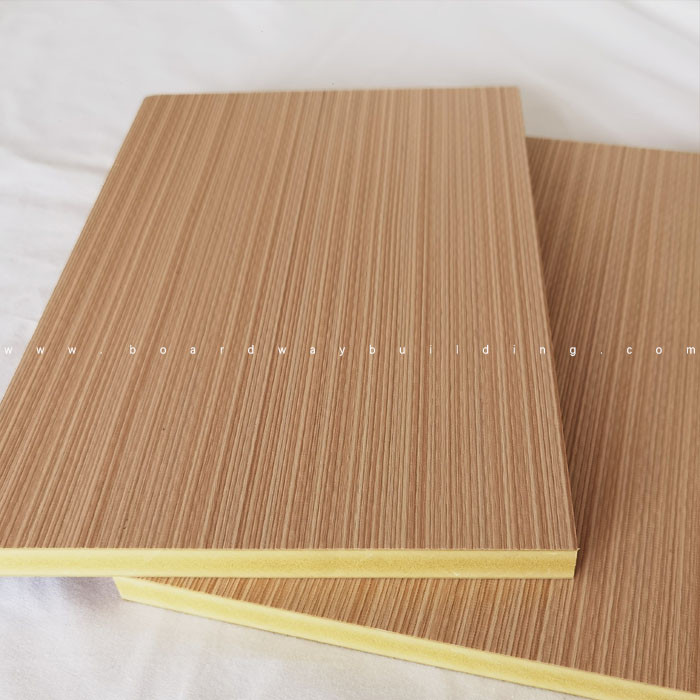

Our available PVC foam board types include high-gloss PVC foam board, matte-textured PVC foam board, wood-grain PVC foam board, and PVC decorative panels with laminated surfaces. This variety empowers automotive designers and enthusiasts to explore various design aesthetics, from sleek and contemporary to rustic and natural, ensuring that every vehicle interior can be tailored to suit individual preferences and project requirements.

High-gloss PVC Foam Board

Matte PVC Foam Board

Wood Grain PVC Foam Board

PVC Decorative Panel

Throughout this article, we have explored the numerous advantages of utilizing PVC foam board in automotive interior modifications. Its lightweight construction, durability, anti-rot properties, ease of fabrication, cost-effectiveness, and design versatility make it a standout choice for designers, manufacturers, and vehicle owners seeking to elevate the quality and appeal of vehicle interiors. From cabinetry and storage solutions to decorative trim and electrical enclosures, PVC foam board offers practical and aesthetic benefits that enhance the functionality and aesthetics of automotive interiors.

By leveraging the diverse capabilities of PVC foam board, automotive interior designers and manufacturers can create innovative and customized solutions that cater to a wide range of vehicle types and applications. Whether it's upgrading storage solutions in trailers, modernizing RV interiors, or retrofitting ambulances with advanced medical equipment, PVC foam board offers the flexibility and performance needed to achieve desired design objectives.

As automotive interior design continues to evolve, PVC foam board remains at the forefront as a reliable and efficient material for enhancing the functionality, aesthetics, and overall quality of vehicle interiors. We encourage automotive industry professionals and enthusiasts alike to consider PVC foam board as a valuable resource for unlocking new possibilities in vehicle interior design. With its unparalleled versatility and performance, PVC foam board is poised to continue making significant contributions to the advancement of automotive interior aesthetics and functionality for years to come.

- Experience the Best in PVC foam board with Boardway

- CONTACT NOW