Understanding WPC Foam Board and PVC Foam Board: Composition and Physical Properties

sourcewww.boardwaybuilding.com

publisherBoardway

time2024/05/20

- Explore the differences between WPC foam board and PVC foam board, including their composition, physical properties, and manufacturing insights. Learn how to select the right foam board material for your project needs.

WPC (Wood-Plastic Composite) foam board and PVC (Polyvinyl Chloride) foam board are two commonly used materials in various industries, each with its unique characteristics and applications. Understanding the composition and physical properties of these materials is essential for making informed decisions when selecting the appropriate material for specific projects.

WPC Foam Board, or Wood-Plastic Composite foam board, is a composite material made from a blend of PVC resin and wood powder. This combination brings together the best of both worlds: the strength and durability of plastic with the aesthetic appeal and workability of wood. The inclusion of wood fibers enhances its rigidity and gives it a more natural look, making it ideal for applications where both performance and appearance matter.

PVC Foam Board, on the other hand, is composed entirely of PVC resin. This makes it lightweight, easy to handle, and highly resistant to moisture and chemicals. Its smooth and uniform surface makes it a preferred choice for applications that require detailed printing or precise cuts. PVC foam board is often used in signage, displays, and indoor construction projects due to its excellent moisture resistance and ease of use.

Recognizing the differences between WPC foam board and PVC foam board is crucial for choosing the most suitable material for diverse applications, ranging from construction and furniture to signage and display. In this article, we will delve into the composition and physical properties of both materials, aiming to provide clarity on their distinctions and assist readers in making informed decisions for their projects.

As a leading manufacturer and supplier, Boardway specializes in providing high-quality WPC and PVC foam boards. With our extensive experience and commitment to quality, we offer a wide range of products tailored to meet diverse project requirements. By choosing Boardway, you can be assured of getting the best materials backed by expert support and reliable service.

Composition and Manufacturing Process

Understanding the composition and manufacturing processes of WPC foam board and PVC foam board is essential to appreciate their unique properties and suitability for different applications.

WPC Foam Board

1. Composition:

WPC foam board is composed of a blend of PVC (Polyvinyl Chloride) resin and wood powder or fiber. Typically, the mixture contains around 90-95% PVC and 5-10% wood powder, although the exact ratio can vary based on the desired properties of the final product. The wood powder used in WPC foam board adds strength, rigidity, and a natural wood-like appearance to the material, enhancing its aesthetic and functional appeal.2. Manufacturing Process:

The manufacturing process of WPC foam board involves several key steps:

1. Material Preparation: PVC resin, wood powder, and additives (such as stabilizers, lubricants, and colorants) are carefully measured and mixed to create a homogeneous blend.

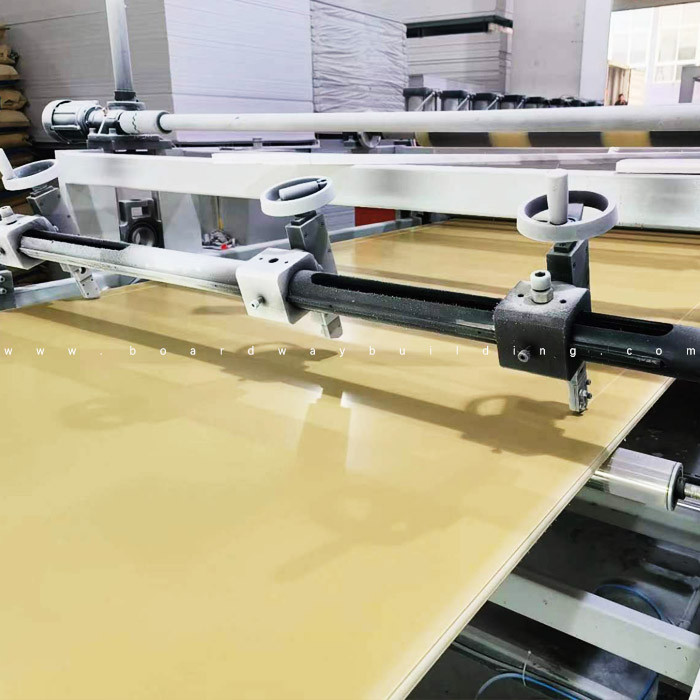

2. Extrusion: The mixture is fed into an extruder, where it is heated and melted. The molten material is then forced through a die to shape it into the desired form (e.g., sheets, boards).

3. Foaming: During extrusion, a foaming agent is introduced to create a cellular structure within the material, reducing its density and weight while maintaining strength.

4. Cooling and Cutting: The extruded material is cooled to solidify its shape and then cut into boards of specified dimensions.

5. Finishing: The boards may undergo additional finishing processes, such as sanding, surface coating, or embossing, to enhance their appearance and performance.

PVC Foam Board

1. Composition:

PVC foam board is composed entirely of PVC resin, which gives it a consistent and smooth texture. It does not contain any wood powder or fibers. Additives such as stabilizers, impact modifiers, and colorants are included to improve the material's performance and appearance.2. Manufacturing Process:

The manufacturing process of PVC foam board is similar to that of WPC foam board but without the addition of wood powder:

1. Material Preparation: PVC resin and additives are thoroughly mixed to ensure uniformity.

2. Extrusion: The mixture is heated and melted in an extruder. The molten PVC is then pushed through a die to form sheets or boards.

3. Foaming: A foaming agent is introduced during extrusion to create a cellular structure, reducing the material's density and weight.

4. Cooling and Cutting: The extruded PVC foam board is cooled to solidify its shape and then cut to the desired size.

5. Finishing: The boards may be finished with processes like sanding, printing, or laminating to achieve the required surface characteristics.

Impact on Final Product Properties

1. Strength and Durability:

2. Weight:

3. Aesthetic Appeal:

4. Moisture and Chemical Resistance:

Both WPC and PVC foam boards offer excellent moisture and chemical resistance. However, WPC foam board may have slightly lower moisture resistance due to the wood content, which can absorb water if not properly sealed.

5. Environmental Impact:

By understanding these differences in composition and manufacturing processes, you can better appreciate the unique properties of WPC foam board and PVC foam board and make informed decisions based on the specific needs of your project.

Physical Properties

When selecting the appropriate material for your project, it's essential to understand the physical properties of both WPC foam board and PVC foam board. These properties include durability, weight, moisture resistance, and aesthetic appeal, each of which can significantly influence the material's suitability for specific applications.

1. Durability

WPC Foam Board

PVC Foam Board

2. Moisture Resistance

WPC Foam Board

PVC Foam Board

3. Aesthetic Appeal

WPC Foam Board

PVC Foam Board

In summary, both WPC foam board and PVC foam board offer distinct physical properties that make them suitable for different applications. WPC foam board excels in strength, durability, and a natural aesthetic, making it ideal for both indoor and outdoor use. PVC foam board, with its lightweight nature, excellent moisture resistance, and smooth finish, is perfect for indoor applications and environments where ease of installation is crucial. By understanding these physical properties, you can make informed decisions about which material best meets the needs of your specific project.

This article has provided an overview of WPC (Wood-Plastic Composite) foam board and PVC (Polyvinyl Chloride) foam board, highlighting their composition and physical properties. Understanding these differences helps readers make informed decisions for their projects. With WPC foam board offering enhanced strength and a natural appearance, and PVC foam board providing lightweight versatility and moisture resistance, it's crucial to assess project needs carefully. By considering these factors, designers can ensure successful outcomes.

Stay tuned for the next article, which will delve into a comparison between WPC foam board and PVC foam board, focusing on workability, installation, and other important considerations. We invite readers to explore further to gain a comprehensive understanding of these materials.