Can laminated PVC foam board be used outdoors?

sourcewww.boardwaybuilding.com

publisherBoardway

time2024/07/22

- Explore the differences between indoor-grade and outdoor-grade laminated PVC foam boards and understand why selecting the right type is essential for durability. Boardway, a leading Chinese manufacturer, provides customized solutions to meet all your PVC foam board needs.

Laminated PVC foam board is a versatile material known for its lightweight, durable, and aesthetically appealing properties. It is widely used in various applications, from indoor signage to decorative elements. Boardway, a leading manufacturer and supplier based in China, specializes in providing high-quality PVC foam boards tailored to meet diverse needs. Our expertise and commitment to excellence ensure that our laminated PVC foam boards deliver exceptional performance, whether for indoor or outdoor use.

Understanding Laminated PVC Foam Board

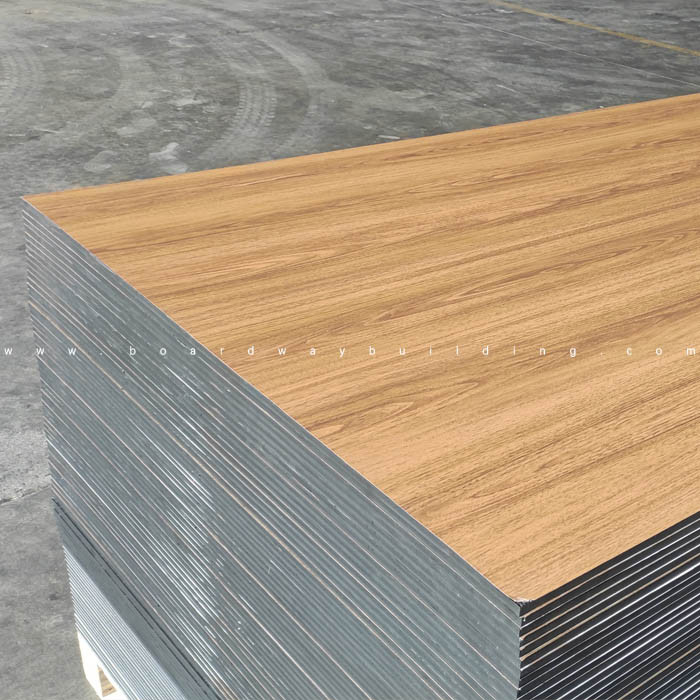

Laminated PVC foam board is a composite material featuring a PVC foam core that is laminated with a decorative surface layer, typically made of PVC film. This combination provides a lightweight yet sturdy board suitable for various applications. There are two primary types: indoor-grade and outdoor-grade. Indoor-grade laminated PVC foam board is designed for use in protected environments, offering aesthetic appeal and cost-effectiveness. In contrast, outdoor-grade laminated PVC foam board is engineered to withstand harsh environmental conditions, such as UV exposure, rain, and snow, ensuring durability and longevity in outdoor applications.

Testing Indoor-grade Laminated PVC Foam Board Outdoors

To evaluate the suitability of indoor-grade laminated PVC foam board for outdoor use, a comprehensive test was conducted by a customer in Wisconsin, USA. The test involved placing the boards in an outdoor environment for extended periods—specifically, 8 months and 18 months. The test conditions included exposure to typical weather elements such as rain, UV rays, and snow.

During the testing phase, several key observations were made:

The core material of the PVC foam board, which serves as the structural base, remained intact throughout the test periods. There were no visible signs of aging, deterioration, or disintegration, indicating that the base material is robust and durable under various weather conditions.

The lamination process, which involves adhering the decorative surface to the PVC foam core, continued to perform well. The adhesive layer held the PVC film securely in place without any noticeable delamination or failure. This suggests that the lamination method used is effective in maintaining the bond between layers.

The most significant issue observed was with the PVC film surface layer. The wood-grain film, intended to provide a decorative finish, exhibited several problems. Notably, the surface began to peel and detach with light scratching. Additionally, the appearance of the wood-grain pattern changed over time. Both the deep gray and cream-colored wood-grain samples showed minor fading, while the light gray wood-grain sample experienced more severe discoloration. This indicates that the PVC film is not sufficiently durable for prolonged outdoor exposure, where it is exposed to environmental stressors such as UV radiation and moisture.

In summary, while the indoor-grade laminated PVC foam board performed adequately in terms of structural integrity and adhesive bonding, the surface layer did not withstand the outdoor elements effectively. This highlights the necessity of using outdoor-grade laminated PVC foam board for applications exposed to harsh environmental conditions, ensuring better longevity and performance.

Why Indoor-grade Laminated PVC Foam Board Is Not Suitable for Long-term Outdoor Use

Indoor-grade laminated PVC foam board is designed for environments where it is protected from harsh weather conditions. Its primary application is in indoor settings where factors like UV exposure, rain, and extreme temperatures are minimal. However, the test results have demonstrated several critical issues that make indoor-grade laminated PVC foam board unsuitable for long-term outdoor use:

1. Issues with the PVC Film Layer

The most significant problem observed is with the PVC film surface layer. This decorative layer, intended to provide an appealing finish, is not engineered to withstand the rigors of outdoor conditions. Under exposure to UV rays, rain, and snow, the PVC film begins to degrade. The film shows signs of peeling and detachment, as well as noticeable fading of the wood-grain pattern. The extent of fading varies with the color of the film, with lighter colors experiencing more severe discoloration. This degradation compromises the aesthetic quality and protective function of the board.

2. Importance of Using the Right Grade of Materials

Selecting the appropriate grade of laminated PVC foam board is crucial for ensuring performance and longevity in specific environments. Indoor-grade materials are not designed to handle prolonged exposure to environmental stressors like UV radiation and moisture. For outdoor applications, it is essential to use outdoor-grade laminated PVC foam board, which is specially formulated to resist weathering, UV damage, and moisture infiltration. This ensures that the material maintains its structural integrity and visual appeal over time, making it a more reliable choice for outdoor use.

In summary, while indoor-grade laminated PVC foam board performs well in controlled, indoor settings, its surface layer fails to endure outdoor conditions, leading to issues such as peeling and fading. For applications exposed to the elements, outdoor-grade laminated PVC foam board is the recommended choice to ensure durability and long-term performance.

Choosing the Right Laminated PVC Foam Board for Your Needs

Selecting the appropriate laminated PVC foam board for your project is crucial to ensure that it meets your performance and durability requirements. Here’s a guide to help you make an informed decision:

1. When to Use Indoor-grade Laminated PVC Foam Board:

Indoor Environments: Indoor-grade laminated PVC foam board is ideal for use in controlled, indoor settings where exposure to harsh weather conditions is minimal. It is well-suited for applications such as interior signage, decorative panels, and point-of-sale displays.

Occasional Outdoor Use: If the board will only occasionally be exposed to outdoor conditions and is not subject to prolonged exposure, indoor-grade boards may be sufficient. However, it's important to monitor for any signs of wear or damage.

2. Benefits of Using Outdoor-grade Laminated PVC Foam Board for Outdoor Applications:

Enhanced Durability: Outdoor-grade laminated PVC foam board is specifically designed to withstand the rigors of outdoor environments. It features a more robust PVC film layer that resists UV rays, moisture, and temperature fluctuations, ensuring long-term performance.

Weather Resistance: This type of board provides excellent resistance to environmental factors such as rain, snow, and sunlight, making it suitable for outdoor signage, architectural elements, and other applications exposed to the elements.

Long-Term Reliability: With its superior durability, outdoor-grade PVC foam board maintains its structural integrity and visual appeal over time, reducing the need for frequent replacements or repairs.

3. Factors to Consider:

Environment: Evaluate the environmental conditions where the board will be used. For indoor applications, indoor-grade boards are typically adequate. For outdoor use, consider outdoor-grade boards to handle exposure to weather and UV light.

Duration of Use: Determine how long the board will be in use. For temporary or short-term applications, indoor-grade boards might suffice. For long-term outdoor projects, outdoor-grade boards are recommended to ensure durability.

Specific Applications: Consider the specific requirements of your project, including the need for visual appeal, structural strength, and resistance to environmental factors. Choose the grade of laminated PVC foam board that best matches these needs to achieve optimal performance.

By carefully considering these factors, you can select the right laminated PVC foam board to meet your project's demands and ensure satisfactory performance and longevity.

Boardway's Laminated PVC Foam Board Solutions

Boardway offers a comprehensive range of laminated PVC foam boards designed to meet diverse needs, from indoor to outdoor applications. Our product range includes both indoor-grade and outdoor-grade options, tailored to deliver exceptional performance in various environments. We provide extensive customization services, allowing you to select specific thicknesses, finishes, and sizes to suit your project requirements. For inquiries or to make a purchase, please contact us directly through our website or customer service team to receive expert guidance and high-quality solutions tailored to your needs.

Choosing the right type of laminated PVC foam board is crucial for ensuring the durability and effectiveness of your project. Indoor-grade boards are suitable for controlled environments, while outdoor-grade options are essential for enduring harsh weather conditions. For tailored advice and high-quality products that meet your specific needs, contact Boardway, a leading provider of PVC foam boards. Our expert team is ready to assist you in selecting the ideal solution for your application, ensuring optimal performance and satisfaction.