Bad Things About PVC Foam Sheet You Should Know

sourcewww.boardwaybuilding.com

publisherBoardway

time2022/06/08

- PVC foam board has many advantages such as waterproof, lightweight, easy to process. But it is not resistant to high temperature and turns yellow outdoors. Find out pros and cons of PVC foam board.

What is PVC Foam Board?

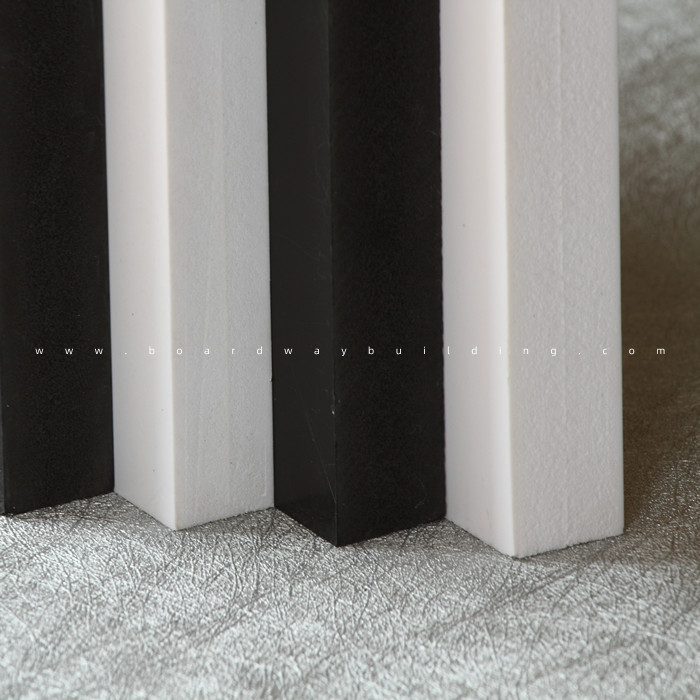

PVC foam board, also known as expanded PVC sheet. It is a rigid, closed-cell, foamed PVC sheet with half the density of solid PVC sheet, which gives it a lighter weight. PVC foam board is suitable for most indoor and outdoor applications due to its high usability and durability, and is an ideal alternative to wood board. PVC foam board is widely used as a multifunctional board, such as sign boards, display boards, kitchen cabinets, interior decoration, wall panels and construction. However, do you know what are the disadvantages of PVC foam board?

Click here to watch the PVC foam board video.

You Told Me Not to Choose PVC Foam Board, Why?

1. Not heat-resistant

The softening temperature of PVC foam board typically ranges from 65°C (149°F) to 80°C (176°F). This implies that in environments with temperatures exceeding this range, PVC foam board can become soft and may even lose structural stability. Using PVC foam board in high-temperature conditions could result in material deformation, failure, or performance degradation.

2. Lacks natural wood grain

While PVC foam board, as a synthetic material, lacks the natural grain patterns found in solid wood, this characteristic doesn't preclude us from enhancing its appearance by applying laminated decorative materials to its surface. This method allows us to achieve a wood-like texture and look, while still benefiting from PVC foam board's advantages like lightweight, insulation, and ease of fabrication.

3. White PVC foam boards may yellow when used outdoors

White PVC foam boards used outdoors may develop a yellowing effect over time. Although the yellowing is typically mild, it might still be unsatisfactory for some customers. We recommend customers consider purchasing ivory-white PVC foam boards instead of pure white ones, or opt for PVC foam boards with enhanced UV resistance to mitigate this issue.

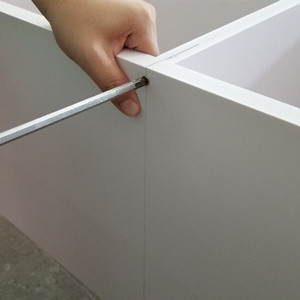

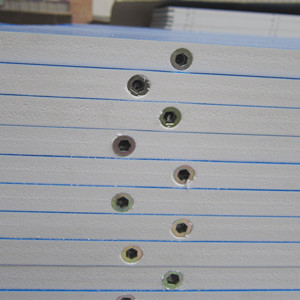

4. Weak screw holding strength

Concerns about the screw-holding capacity of PVC foam boards are often rooted in comparisons with solid wood. This discrepancy arises from the inherent contrast between the expanded closed-cell structure of PVC foam and the wood fiber structure. Nonetheless, we can enhance the screw-holding strength of PVC foam boards through more effective fasteners and installation methods. Furthermore, higher-density PVC foam boards exhibit improved screw-holding capabilities.

5. PVC is toxic when burned

Polyvinyl chloride (PVC), when burned, can release harmful substances such as chlorine gas, hydrogen chloride gas, and carbon monoxide. These gases and smoke have the potential to pose health risks to human beings. Generally, PVC begins to degrade and release toxic gases within a temperature range of approximately 150°C (302°F) to 200°C (392°F).

Despite these limitations, PVC foam boards offer a range of advantageous qualities that make them a valuable choice for various applications. Let's explore the benefits they bring to the table.

Advantages of PVC Foam Board

1. Lightweight for Effortless Handling and Installation

The density of standard PVC foam board typically ranges from 0.5 to 0.65g/cm3, which is less than half that of solid PVC sheets and comparable to some wood panels. This lightweight property ensures easy handling and straightforward installation.

2. Water and Moisture Resistance

PVC foam board exhibits minimal water absorption, making it highly resistant to water and moisture. This quality proves invaluable in humid environments.

3. Corrosion Resistance

Polyvinyl chloride boasts resistance to acids, alkalis, and a range of chemicals, mitigating concerns about corrosion or rust in practical applications.

4. Termite and White Ant Resistance

PVC foam board is unappealing to termites and white ants, rendering indoor furniture crafted from it unattractive to these pests.

5. Self-Extinguishing Fire Resistance

Common PVC foam board possesses self-extinguishing properties in fire conditions. Fireproof reinforcement variants can even meet ASTM E84 Class A standards.

6. UV Resistance

PVC foam boards, compared to wooden counterparts, resist crushing and cracking in outdoor use, contributing to a longer service life. UV-resistant variants perform exceptionally well, especially when enhanced with anti-ultraviolet agents.

7. High Strength

Depending on its density, PVC foam board can exhibit remarkable rigidity or flexibility, catering to varying strength requirements.

8. Ease of Processing

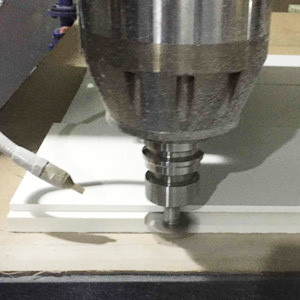

PVC foam board can be conveniently drilled, nailed, sawed, CNC cut, hot bent, laminated, sanded, and painted without the need for specialized equipment or tools.

9. Printable

PVC free foam board, one of three types of PVC foam board, offers a matte finish and ample size, making it ideal for printing and signage applications.

10. Versatile Design Flexibility

PVC foam boards excel in design versatility, offering an array of possibilities for cutting, shaping, and customization. This adaptability allows for the creation of intricate and diverse designs, making them suitable for a wide range of creative and practical applications.

Where Is PVC Foam Sheet Commonly Used?

While PVC foam sheet does have some limitations, it remains one of the most versatile plastic materials across many industries. Thanks to its lightweight nature, durability, and ease of fabrication, it continues to be a popular choice in both commercial and residential settings. Here are some of its most common applications:

Interior Decoration

PVC foam boards are widely used for wall panels, ceiling tiles, room partitions, and decorative backgrounds. They offer a smooth, printable surface and can be laminated with wood grain or marble finishes for an elegant look.

Furniture and Cabinets

Laminated PVC foam boards are a great alternative to traditional wood panels in making cabinets, bathroom vanities, and lightweight furniture. They are termite-resistant, waterproof, and easy to clean.

Signage and Display

Due to its excellent printability and smooth surface, PVC foam sheet is ideal for advertising boards, exhibition displays, shop signs, and indoor graphics. It's compatible with screen printing, digital printing, and vinyl lamination.

Transportation and Vehicles

In commercial vehicles like buses and RVs, PVC foam board is often used as interior wall cladding, ceiling panels, and flooring baseboards. Its resistance to moisture and fire-retardant options make it suitable for these demanding environments.

Frequently Asked Questions about PVC Foam Sheet

1. Is PVC foam sheet safe for indoor use?

Yes, PVC foam sheet is generally safe for indoor use, especially when made from virgin materials and free from heavy metals. Always look for RoHS- and REACH-compliant products for better environmental and health protection.

2. Can PVC foam board be painted or printed?

Absolutely. Its smooth surface makes it suitable for painting, screen printing, UV printing, and vinyl lamination. It’s widely used in signage and decorative wall panels.

3. Is PVC foam sheet waterproof?

Yes, PVC foam sheet is 100% waterproof. It does not absorb moisture, making it ideal for use in kitchens, bathrooms, and humid environments.

4. How long does PVC foam sheet last?

PVC foam sheets can last 5 to 10 years or even longer depending on usage, environmental exposure, and whether the sheet is used indoors or outdoors. For indoor decorative applications, it maintains its performance for a long time.

5. What’s the difference between PVC foam board and traditional wood in decoration?

Unlike wood, PVC foam board is waterproof, termite-resistant, lightweight, and easier to fabricate. It doesn’t warp or rot, making it a low-maintenance alternative for many decorative projects.

Understanding the drawbacks of PVC foam boards may not necessarily steer us away from them. Rather, it prompts us to combine their strengths and weaknesses for more judicious applications across various industries. In the upcoming blog posts, we will delve into how we, as PVC foam board manufacturers, are contributing to the recycling and reutilization of these materials. By embracing a holistic perspective, we aim to make the most of PVC foam boards while also addressing environmental considerations.

- Want to learn more about PVC foam boards? Visit our PVC Foam Board main page.

- READ MORE

Boardway is a Chinese manufacturer and supplier of PVC foam board. We have more than 15 years of experience in the manufacture and application of PVC foam board and other plastic sheets. If you would like to know more about PVC foam board, or you have the needs of custom PVC foam board, please feel free to WhatsApp Helen at +86 13828266785 or email us at sale..........com.

Boardway Processing Services

1. Cut to size and CNC engraving

2. Silk screen printing, digital printing, painting

3. Thermal processing, bending, embossing

4. Pre-drill, nail, screw and assemble

5. Sanding, PUR lamination, PVC edge banding

6. Corners and edges rounding, chamfering, grooved and tongued

Click here to visit our factory.