PVC Foam Board Laminate

A LAMINATED PVC BOARD FOR DECORATION AND FURNITURE MAKING

PVC foam board laminates involve applying a thin surface material to one or both sides of PVC or WPC foam boards. This lamination not only enhances the board's appearance but also improves its performance, providing additional options to meet various application requirements.

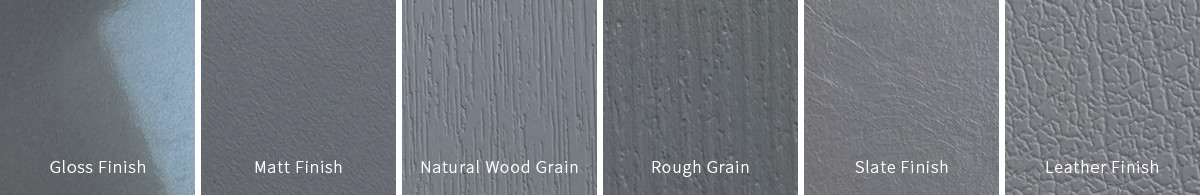

There are a variety of surface materials available for PVC/WPC foam board lamination, including PVC film, PETG film, high-pressure laminate (HPL), aluminum sheets or films, and acrylic sheets. Surface patterns range from plain colors to wood grain, marble, fabric, and more, while texture options include smooth, frosted, matte, wood grain, slate, leather, and others.

With such a broad range of surface materials and textures, PVC/WPC foam board laminates offer great flexibility, making them suitable for different decorative styles and application needs.