How Can You Perfect Your PVC Foam Board Projects?

sourcewww.boardwaybuilding.com

publisherBoardway

time2023/12/28

- Unlock the secrets of flawless PVC foam board crafting with expert techniques. Explore customized solutions for durable projects. Perfect your creations with expert joining and bonding. Boardway, your trusted PVC foam board manufacturer, brings you precision and customization for unmatched results.

Are you ready to elevate your PVC foam board projects to new heights? Join us on a journey through the intricacies of crafting durable and visually stunning structures. From mastering joining and bonding techniques to adding those impeccable finishing touches, discover the secrets to ensuring your PVC foam board creations stand out. At Boardway, we not only bring you quality as China's leading manufacturer and supplier but also offer a world of customization possibilities. Let's delve into the art of perfecting your PVC foam board projects.

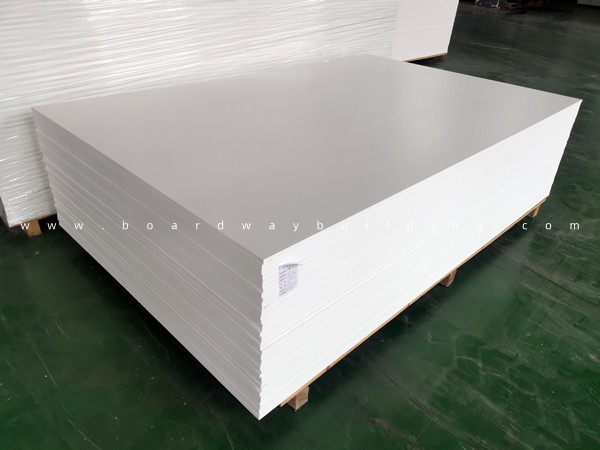

PVC Foam Board Manufacturer

Black PVC Foam Board

Section 1: Joining and Bonding Techniques

Creating sturdy and durable structures with PVC foam board involves effective joining and bonding. Here, we explore techniques and considerations for seamless connections:

1. Selecting the Right Adhesive:

Choose adhesives specifically formulated for PVC foam board. Consider the project's requirements, such as indoor or outdoor use, to select the appropriate adhesive type.

2. Surface Preparation:

Ensure surfaces to be bonded are clean and free from dust. Use a mild solvent to clean if necessary, allowing for optimal adhesive adhesion.

3. Even Adhesive Application:

Apply adhesive evenly to both surfaces. Use an adhesive applicator or a suitable tool to ensure uniform coverage.

4. Clamping for Proper Bonding:

Use clamps to hold pieces together during the bonding process. Follow the recommended curing time to allow for a strong bond.

5. Consideration for Temperature:

Bonding in moderate temperatures is ideal for adhesive effectiveness. Extreme temperatures can affect the curing process, so be mindful of the working environment..

6. Avoiding Overuse of Adhesive:

Apply adhesive sparingly to prevent excess from squeezing out when pieces are joined. Excess adhesive can be challenging to clean and may affect the visual appeal of the project.

7. Testing Bonded Pieces:

Before proceeding with the entire project, conduct a small-scale test to ensure the chosen adhesive performs as expected.

8. Understanding Adhesive Characteristics:

Different adhesives have varying cure times and bonding strengths. Consider these characteristics based on the project's demands.

By mastering these joining and bonding techniques, you enhance the structural integrity of your PVC foam board projects, ensuring longevity and reliability. In the subsequent section, we will explore finishing touches and surface treatments to elevate the visual appeal of your creations.

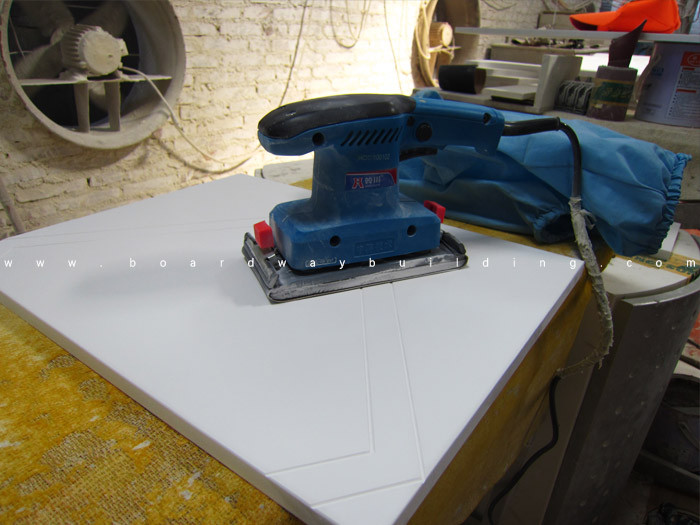

PVC Foam Board Polished

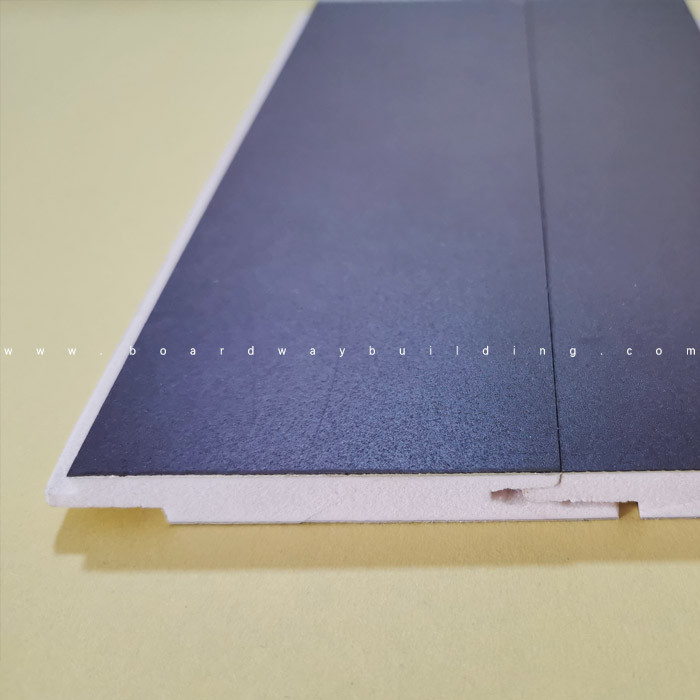

Double Bevel PVC Foam Board

Round Edge PVC Foam Board

Section 2: Finishing and Surface Treatment

Achieving a polished and refined appearance for your PVC foam board projects involves careful finishing and surface treatments. Here are essential techniques to enhance the visual appeal:

1. Edge Finishing:

Use sandpaper or a sanding block to smooth rough edges. Create a clean and professional look by rounding or beveling edges.

2. Painting and Coating:

Apply paints or coatings suitable for plastics to enhance aesthetics. Ensure proper adhesion by cleaning the surface before painting.

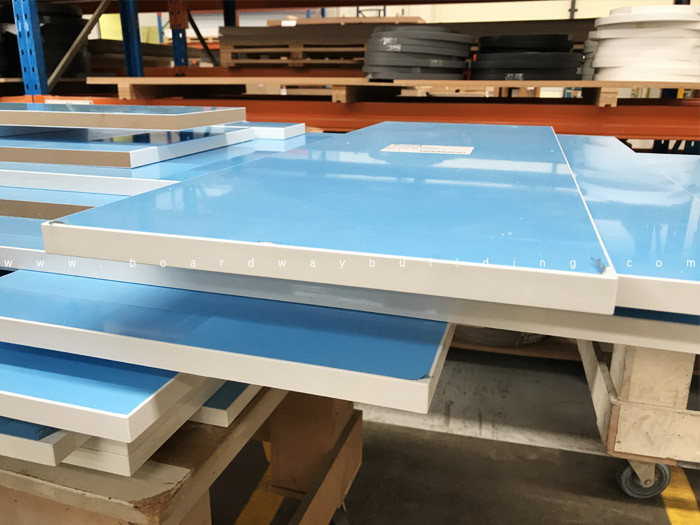

3. Lamination for Decoration:

Consider lamination not just for protection but as a decorative element. Utilize diverse laminate materials such as PVC film, PETG film, HPL sheets, aluminum, acrylic sheets, etc. Choose laminates based on patterns, textures, and finishes to complement the project's design theme.

4. Embossing and Engraving:

Use CNC machines for embossing or engraving designs onto the surface. Adds a personalized and decorative touch to the project.

5. Consideration for Outdoor Use:

If the project will be exposed to outdoor elements, use materials and finishes that resist weathering. UV-resistant coatings help prevent color fading.

6. Cleaning and Maintenance:

Provide guidelines on cleaning methods for different finishes. Educate users on proper maintenance to prolong the life and appearance of the PVC foam board.

7. Quality Inspection:

Before finalizing the project, conduct a thorough quality inspection. Check for any imperfections, ensuring a flawless finished product.

By incorporating these finishing techniques, you not only enhance the aesthetic appeal of your PVC foam board projects but also contribute to their overall durability and longevity. In the concluding section, we will recap the key considerations and encourage users to explore the full potential of PVC foam board in their creative endeavors.

Edge banding processing

Edge-sealed PVC foam board

Section 3: Common Mistakes to Avoid

Even with the best tools and techniques, common mistakes can hinder the success of PVC foam board projects. Here are pitfalls to avoid:

- Inadequate Surface Preparation: Skipping proper cleaning and preparation can compromise adhesive bonds and finishing.

- Overlooking Tool Maintenance: Dull or improperly maintained tools result in imprecise cuts and a subpar finish.

- Excessive Use of Adhesive: Applying too much adhesive leads to messy joints and can negatively impact the visual appeal.

- Ignoring Safety Precautions: Neglecting safety gear and precautions increases the risk of accidents and injuries.

- Using Incompatible Adhesives: Selecting adhesives not designed for PVC foam board can result in weak bonds and project failure.

- Neglecting Temperature Considerations: Bonding or processing in extreme temperatures can affect the material negatively.

- Skipping Quality Checks: Failing to inspect the quality of each step can result in flaws that may compromise the project's integrity.

PVC Foam Board Sanding

PVC Foam Board Painting

In your exploration of PVC foam board craftsmanship, keep in mind that perfection is found in the finer details. By avoiding common pitfalls, mastering the art of lamination for decoration, and understanding the nuances of joining and bonding, you're not just creating structures; you're crafting masterpieces. At Boardway, we take pride in being your partner in this creative journey. As a distinguished manufacturer and supplier from China, we not only provide top-notch materials but also stand ready to bring your unique visions to life through our customization services. Your journey doesn’t end here; explore the vast possibilities of PVC foam board in your creative endeavors.

As you delve into the complex world of perfecting your PVC foam board project in this article, have you explored the essential techniques for effective processing in our companion guide, "How to Process PVC Foam Board Effectively?" Discover the crucial steps to ensure precision from the very beginning of your project. Mastering the processing techniques is the foundation for creating exceptional PVC foam board structures. If you haven't already, click here to explore the fundamentals of effective processing before diving into the finer details of perfection in the realm of PVC foam board craftsmanship. At Boardway, where innovation meets expertise, we guide you every step of the way. Click now to enhance your skills and perfect your PVC foam board projects!

- Experience the Best in PVC foam board with Boardway

- CONTACT NOW