What is the Difference Between WPC Foam Board and PVC Foam Board?

sourcewww.boardwaybuilding.com

publisherBoardway

time2024/05/13

- Discover the key differences between WPC foam board and PVC foam board in this comprehensive comparison. Learn about their unique properties and characteristics and explore the manufacturing processes, physical properties and applications of WPC and PVC foam boards to find the product that best suits your needs.

When choosing materials for your construction or design projects, understanding the differences between WPC foam board and PVC foam board is crucial. Both materials offer unique benefits, but their distinct properties can make one more suitable than the other depending on the application. Boardway, a leading manufacturer and supplier, provides high-quality WPC and PVC foam boards to meet diverse project needs.

1. Composition and Manufacturing Process

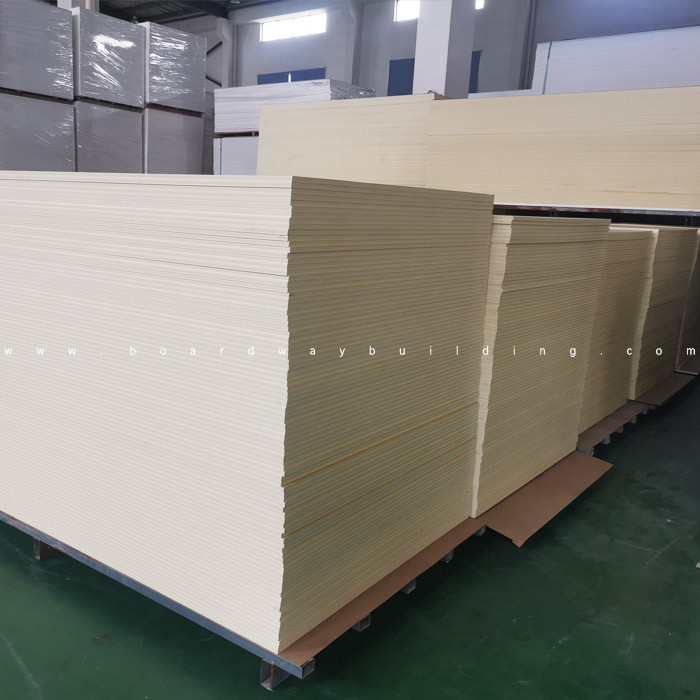

WPC Foam Board: Made from a blend of PVC resin and wood powder, WPC foam board combines the best qualities of both materials. The wood powder adds strength and a natural aesthetic, while the PVC resin ensures durability and moisture resistance.

PVC Foam Board: Composed entirely of PVC resin, this material is lightweight, easy to work with, and offers excellent moisture resistance. The manufacturing process involves extruding the PVC resin into foam boards, resulting in a uniform and smooth finish.

The inclusion of wood powder in WPC foam board enhances its rigidity and structural integrity, making it more suitable for applications requiring additional strength.

2. Physical Properties

Click to view a more detailed article on the following content: Understanding WPC Foam Board and PVC Foam Board: Composition and Physical Properties

3. Workability and Installation

Both WPC and PVC foam boards are easy to cut, shape, and machine using standard woodworking tools. However, WPC foam board may require slightly more effort due to its added rigidity.

Installation processes for both materials are straightforward, but the choice of adhesives and fasteners may vary based on the specific requirements of each material.

4. Applications

PVC Foam Board: Commonly used for indoor applications such as signage, displays, printing, and crafts. Its lightweight nature and smooth finish make it ideal for these uses.

WPC Foam Board: Preferred for outdoor applications like signage, cladding, decking, and furniture due to its enhanced durability and weather resistance. Its natural appearance also makes it suitable for decorative indoor uses.

Comparative Analysis: When choosing between the two, consider the specific demands of your project. WPC foam board is better suited for environments where strength and longevity are crucial, while PVC foam board is ideal for lightweight, indoor projects.

5. Environmental Considerations

WPC Foam Board: Often incorporates recycled wood powder, making it a more sustainable option. Its production process typically results in lower emissions compared to solid wood.

PVC Foam Board: Although durable and recyclable, its environmental impact is generally higher due to the production and disposal processes associated with PVC.

Lifecycle: Both materials are recyclable, but the use of recycled content in WPC foam board gives it an edge in terms of sustainability.

6. Cost Comparison

WPC foam board tends to be more expensive than PVC foam board due to its enhanced properties and more complex manufacturing process.

While PVC foam board is more cost-effective for projects with tight budgets, WPC foam board offers better long-term value for applications requiring superior durability and aesthetics.

Click to view a more detailed article on the following content: Comparing WPC Foam Board and PVC Foam Board: Workability, Applications, and Considerations

In conclusion, understanding the differences between WPC foam board and PVC foam board helps in making informed decisions for your projects. While both materials offer unique advantages, WPC foam board stands out for its enhanced durability and natural appearance, making it suitable for both indoor and outdoor applications. PVC foam board, with its lightweight and smooth finish, excels in indoor applications where ease of use and cost-effectiveness are priorities.

Boardway's expertise as a leading manufacturer ensures that you receive high-quality materials tailored to your specific needs. Whether you choose WPC foam board or PVC foam board, Boardway provides reliable solutions for a wide range of applications.