PVC Moulding vs. Traditional Moulding Materials: A Comprehensive Comparison

sourcewww.boardwaybuilding.com

publisherBoardway

time2025/02/25

- Explore the benefits of PVC moulding over traditional materials like wood and plaster. Learn about durability, cost-effectiveness, and ease of installation with PVC profiles from Boardway, a leading manufacturer in China. Discover the perfect moulding solution for your next project.

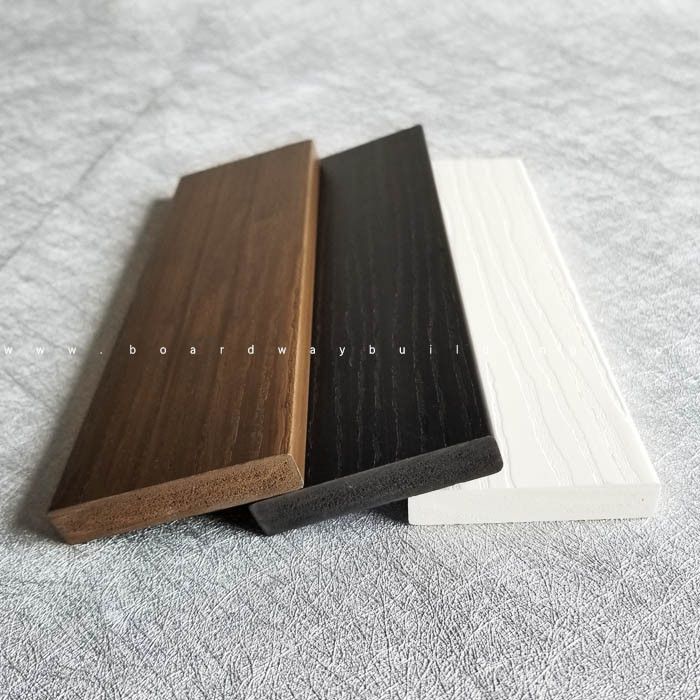

PVC moulding has become increasingly popular in industries like construction, furniture design, and interior decoration due to its remarkable versatility and performance. Unlike traditional moulding materials such as wood or plaster, PVC offers exceptional durability, moisture resistance, and ease of installation, making it a preferred choice for both residential and commercial applications. Choosing the right moulding material is crucial, as it impacts not only the aesthetic appeal of a project but also its long-term durability and cost-effectiveness.

At Boardway, we specialize in manufacturing high-quality PVC foam boards and profiles, backed by over 18 years of experience. As a leading Chinese manufacturer, we provide customized solutions that meet the unique needs of our customers across various sectors. In this article, we'll compare PVC moulding with traditional materials, helping you make an informed decision for your next project.

What is PVC Moulding?

PVC moulding is a type of decorative and functional trim made from foamed PVC (Polyvinyl Chloride), a lightweight and versatile plastic material. The composition of foamed PVC involves adding a foaming agent to the traditional PVC resin, creating a lightweight core that provides strength, durability, and an exceptional surface finish. Unlike solid PVC, foamed PVC offers the benefit of reduced weight without compromising strength, making it an ideal material for moulding applications.

The benefits of PVC as a material for moulding are numerous:

PVC moulding is widely used in a variety of applications, such as:

With its exceptional properties, PVC moulding is fast becoming the preferred choice for modern construction, renovation projects, and decorative designs.

Traditional Moulding Materials

While PVC moulding has become a popular alternative, traditional moulding materials like wood, plaster, and polyurethane have been used for centuries. Each of these materials has its own unique characteristics, advantages, and drawbacks, which are important to consider when choosing the best material for your project.

Wood Moulding

Wood moulding is one of the most traditional and widely used moulding materials. It is typically made from hardwoods like oak, maple, or pine, and is known for its natural appearance and texture. Wood moulding is commonly used in high-end residential homes and commercial buildings, especially when a classic or rustic aesthetic is desired.

Advantages:

Disadvantages:

Plaster Moulding

Plaster moulding is another traditional material that's often used for creating intricate and highly detailed designs. This material is typically cast from molds and is known for its smooth, elegant finish. It is commonly used for ceiling medallions, cornices, and other decorative elements that require fine craftsmanship.

Advantages:

Disadvantages:

Polyurethane Moulding

Polyurethane moulding is a synthetic material that combines the advantages of both foam and plastic, offering a lightweight yet durable solution. It's commonly used for interior applications, such as baseboards, crown moulding, and decorative trims. Polyurethane is often used when PVC is not an option, and it's preferred for designs that require more detailed moulding.

Advantages:

Disadvantages:

In summary, while traditional moulding materials such as wood, plaster, and polyurethane have their merits, each comes with limitations related to durability, ease of installation, and maintenance. These challenges make PVC moulding a viable and increasingly popular alternative in many modern projects, offering distinct advantages that traditional materials cannot always provide.

PVC Moulding vs. Traditional Moulding Materials

When comparing PVC moulding to traditional moulding materials like wood, plaster, and polyurethane, several key factors come into play: durability, cost, maintenance, installation ease, and aesthetic flexibility. Below is a detailed comparison that highlights the strengths of PVC moulding over its traditional counterparts.

1. Durability

2. Cost

3. Maintenance

4. Installation

5. Aesthetic Flexibility

Conclusion: While traditional moulding materials like wood, plaster, and polyurethane have their place, PVC moulding outperforms them in terms of durability, cost, ease of installation, and low maintenance. It offers a practical and stylish solution for modern projects, whether for residential or commercial applications. For those seeking an affordable, long-lasting, and versatile option, PVC moulding is an excellent choice.

In summary, PVC moulding offers numerous advantages over traditional materials like wood, plaster, and polyurethane, including superior durability, ease of installation, cost-effectiveness, and a wide variety of design options. It is an excellent choice for both residential and commercial applications, especially for those seeking a low-maintenance, long-lasting solution. While traditional materials may provide unique aesthetics, PVC moulding's combination of performance and value makes it the ideal option for many projects.

As a leading manufacturer of PVC moulding with over 18 years of experience, Boardway ensures that all products meet the highest standards of quality and performance. We specialize in custom PVC moulding solutions that cater to a wide range of applications, from simple trims to intricate architectural details. Whether for residential, commercial, or industrial use, our products are designed to provide exceptional durability, aesthetic appeal, and cost-effectiveness.

Our expertise allows us to tailor our products to meet specific customer requirements, ensuring that you get the perfect PVC moulding solution for your project. At Boardway, we are committed to delivering top-quality PVC moulding that meets your exact needs, backed by our years of industry experience and commitment to excellence.

- Want to learn more about PVC moulding? Visit our PVC moulding main page.

- READ MORE