WPC Foam Board

SUPERIOR PERFORMANCE WITH A WOOD-LIKE LOOK

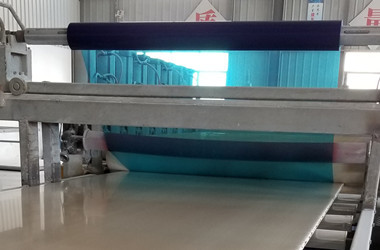

WPC foam board is a versatile material that serves as an excellent alternative to natural wood. It is primarily composed of polyvinyl chloride (PVC) resin, wood powder or bamboo powder, and other additives. This wood-plastic composite panel features a rigid surface and an expanded closed-cell core, produced through foaming extrusion technology.

Similar to expanded PVC foam, WPC foam board offers several advantageous properties, such as low water absorption, formaldehyde-free composition, non-toxic and odorless characteristics, and recyclability. It is widely used in applications like kitchen cabinets, interior decorative panels, and furniture designed for humid environments.

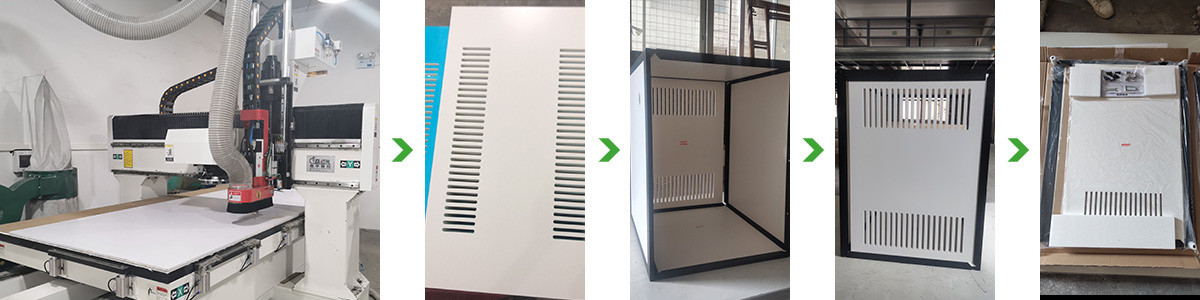

WPC foam board is highly workable and can be easily sawed, cut, drilled, nailed, hot-shaped, painted, and laminated. No special tools are required for processing; conventional woodworking tools are sufficient for shaping and finishing.

Good flatness -

Good flatness - Clean surface -

Clean surface - Stable structure -

Stable structure - Nail-holding strength -

Nail-holding strength - Water-proof & mildew-proof -

Water-proof & mildew-proof - Fire performance -

Fire performance - Suitable as substrate -

Suitable as substrate - Strong workability

Strong workability Sound insulation -

Sound insulation -